|

|

|

Disclaimer:

This is an excerpt of a document written in French by Bruno Saillard

and translated by Bertrand Vogel. |

|

Between 1982

and 1992,

84,909 K100

were produced: |

BMW motorcycle riders must admit that the car technology had made the birth of the K series possible. More precisely, engineers had tested their original idea with a Peugeot 104 engine on the first K prototype!

In 1977, Josef Fritzenweger opened the way for the new concept. This represented a blow to the ideology of boxer engine worshipers but it was for BMW an urgent need to avoid a commercial marginalization like Moto Guzzi with their V twins. BMW had to change their design. Although they were resolutely decided to continue the production of the boxer, they could not take the risk of moving away from the technological innovations that benefited the range of BMW automobiles. The aim was to produce a motorcycle with the most modern techniques, while respecting the broad principles of BMW motorcycles (shaft drive and cylinders in a flat configuration…).

The idea of Josef Fritzenwenger was to have the 4-cylinder engine positioned lengthwise which offers the advantages of an in line engine with the good sides of the boxers. The center of gravity is low, the shaft drive is reliable and the accessibility of the engine is excellent. In addition, a 4-cylinder can easily obtain more power. It is quite economical to build, the noise is manageable and it is so rigid that it may be an element of the motorcycle frame.

For the very first prototype, BMW had selected a foreign engine to test the concept. They used a Peugeot 104 because it is set in the car in an almost flat position, it is cooled by water and its attachment points were close to the idea of Fritzenwegger. Besides, it was an aluminum engine therefore relatively small. The experiment succeeded and a BMW gear box was connected to the engine. The car on 2 wheels demonstrated that it was feasible and the prototype was destroyed. There are no official pictures of it.

|

|

|

|

Encouraged by these results, the research team

began the task of building an engine adapted to the bike and borrowed the

technology from the existing BMW automobiles. The dream of making a versatile

engine for motorcycle and car was the basic objective. The first trials brought

disillusion, because the engine proved to be far too heavy and too long. The

history of K100 suffered its first impasse.

On the 1st of January 1979, Wolfgang Aurich, Karl H Gerlingen and Eberhardt

Sarfert were appointed as head of BMW. They were asked to help to save the

motorcycle production and had to think about a new range of models.

Martin Probst, father of the Volkswagen Golf engine and father of the BMW formula II (which was covered with glory), was appointed director of the engine department - Motorcycle development.

The concept of the future engine was set on February 20, 1979: Compact Drive System, which will be immediately patented. Besides, the K series hold numerous patents to avoid probable Japanese copies.

After the conception on the drawing board, the second phase was the construction of a prototype of the engine. This achievement did not take place without difficulty. The engine was assembled with a temporary exhaust, a manual adjustable timing and a fuel injection system. On August 18 1980, the engine started for the first time. Then they developed the cooling and lubrication system. Two dozen points of measurement were integrated in the cylinders and head to feed the Electronic Fuel Injection with indications about the engine temperature. The cooling system and lubricating system were quickly optimized. The gas combustion was studied and the ideal point of ignition was developed. Several came shafts were tested and the exhaust was developed. Engineers have chosen the electronic injection and it was entrusted to Bosch. In fact no manufacturers were able to supply carburetors small enough to fit this limited space. In addition, BMW had already mastered the electronic fuel injection control. The first tests were encouraging and a power of 90 horsepower was obtained.

The severe endurance test on the bench (10,000 hours) revealed that the basic construction was strong. The tests of the rubber bumpers on the output shaft were problematic. With the heat of the engine oil, the material disintegrated. Seals also caused more research than anticipated. The chemical composition of each seal had to be studied separately. The engine was tested for 500 hours and monitored by a computer. It is common place today but it was not in 1980. The speed and load was constantly varied. The oil was heated to extreme temperatures and thermal shocks were caused by injecting ice cold water into the cooling system. This represented 50,000 km in the worst conditions. After these tests, the K589 prototype was ready for the first road tests.

In autumn 1981 the first two models took the road under a coarse camouflage. They were equipped with two modified flat-twin exhausts and an electronic injection was temporary adjusted. They made 60,000 km each. In spring 1982, the 2 prototypes were modified with all the necessary adjustments resulting of the road tests.

Three new prototypes were again tested by

engineers, mechanics and pilots at the test track of Fiat (Nardo in southern

Italy). From morning till night, the pilots ran around the 12 km track. Each

motorcycle rode 30,000 km. It turned out that the development of Bosch EFI still

left to be improved at high speed. The engines were covered with oil because the

seals were not adequate. That is why the BMW team went for a new set of test at

Nardo in autumn 1982. The tests at high speed allowed making many changes.

On May 2 1983, the first 25 bikes came out of the Berlin factory. These models

had to make a pre-250,000 km each before the K100 was finally presented to the

public.

In September 1983, an international presentation occurred on the Cote d'Azur(French Riviera). The K100 were first loaned to journalists of major motorcycle medias for a quick test and then they were given to BMW dealers present at the event.

The first models were officially released to the public immediately after the 1983 Paris motorcycle show as it was sixty years earlier for the R32.

After decades of slow changes, BMW had developed a motorcycle radically different from what existed in the BMW (as well as the competition) range. The responses from the press were quite positive but the usual BMW clients were particularly shocked.

The year 1985 saw the emergence of a K100 touring series equipped with windshield and higher handlebars.

The K100 was manufactured from 1983 to 1991. BMW produced 12,871 K100 base model, 34,804 K100RS, 22,335 K100 RT, and 14,899 K100LT. The only difference on the K100RS is a different ratio of the differential.

The first models were not designed to run with unleaded gas. This modification started only in January 85 for K100 with frame number 0007291, November 1984 for the K100 RS (frame number 081107) and frame number 0024999 for the K100RT.

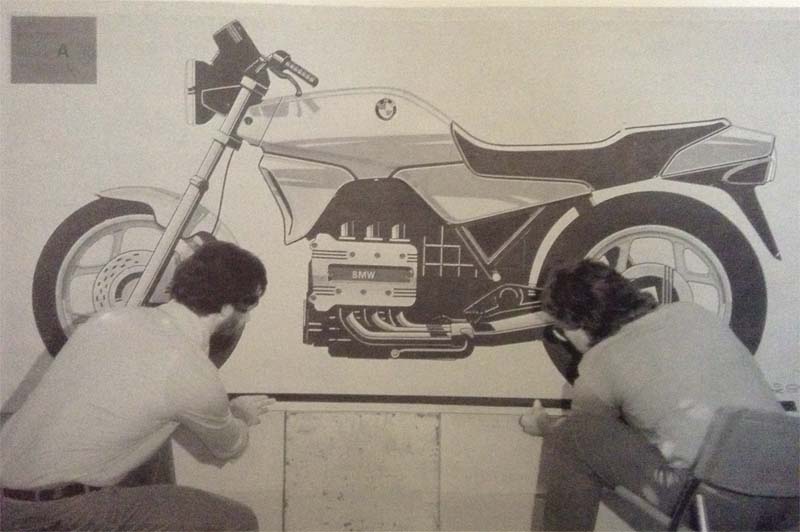

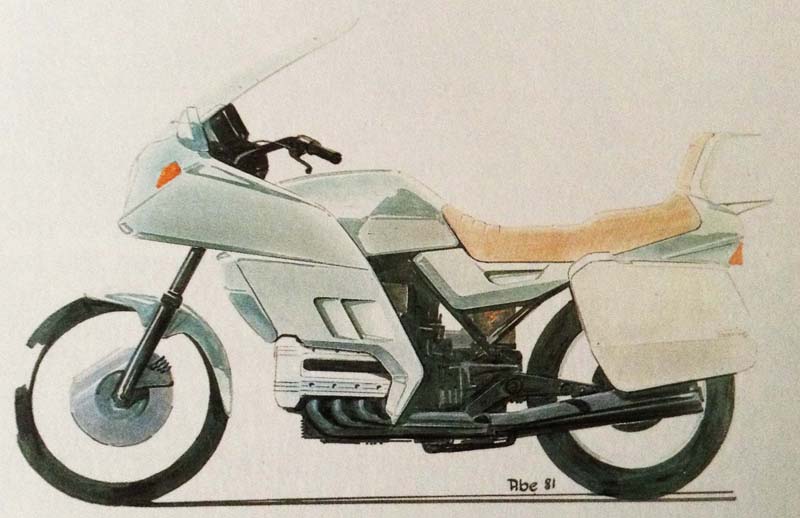

Few pictures taken during the development of the K100:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

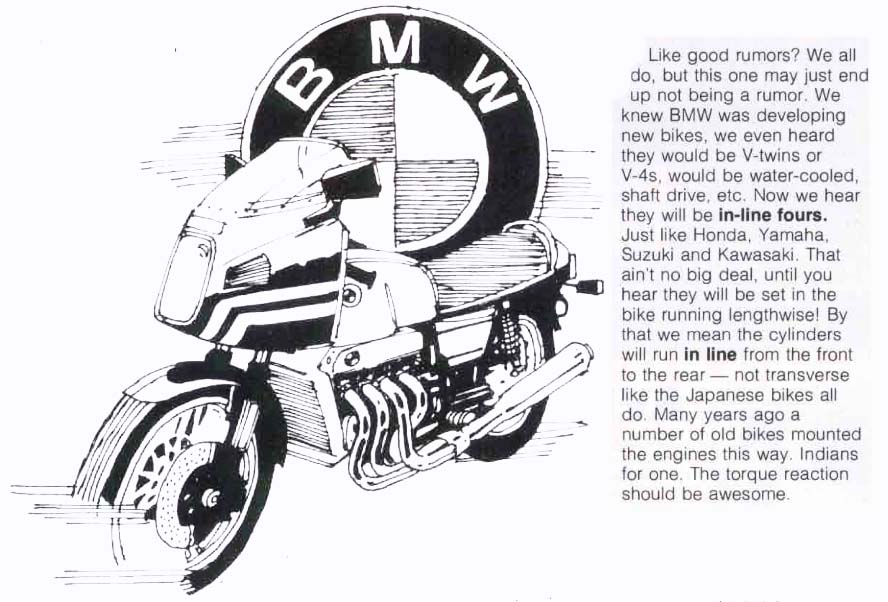

In the late 70's, it was already a rumor going around that BMW was

developing a 4 cylinders.

Here is what people where anticipating:

Bertrand Vogel (Crazy Frog, K100-forum.com)

30 years later, the K100 is still a motorcycle of choice.