Different fuel sender units

and testing methods

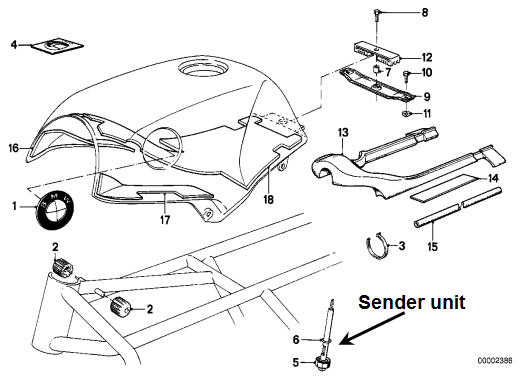

The early models are equipped with an electronic sender

unit.

There are two thermistors housed in the fuel sender unit which is

located in the fuel tank. The thermistors are positioned at two

different levels corresponding to 7 and 4 litres.

When the thermistor is

exposed to the air in the tank the appropriate light is illuminated.

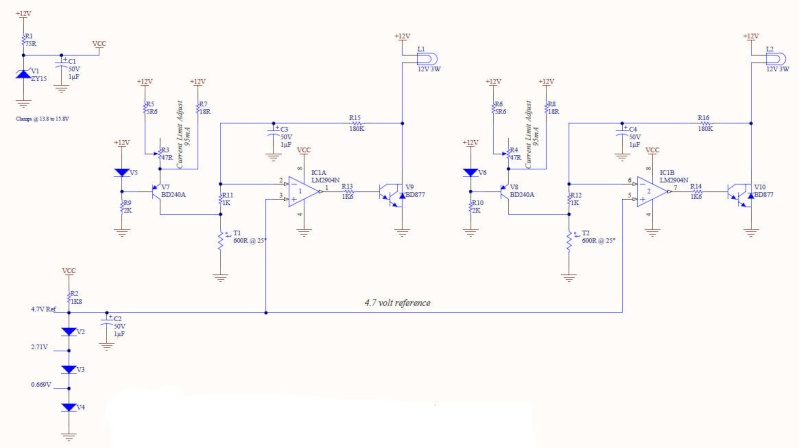

Each thermistor is supplied with 12 volts that is current limited to

95mA, this current limit is controlled by the BD240A's and there

accompanying circuitry.

With the applied voltage the thermistors self

heat, when they are immersed in fuel the heat is dissipated and the

resistance is approximately 600 ohms.

While the thermistor is immersed

in fuel the inverting input of the op-amp has 12 volts applied to it.

This voltage level is above the 4.7 volt reference applied to the

non-inverting input of the op-amp and thus the output of the op-amp is

below the 0.7 volts needed to turn on the NPN transistor (BD877) which

controls the lamp. When the thermistor is above the fuel level and in

air, the self heating causes its resistance to drop below 53 ohms, the

voltage at the inverting input of the op-amp drops with it to below the

4.7 volt reference level applied to the non-inverting input of the

op-amp. This causes the output of the op-amp to swing to its maximum

positive level (+12V).

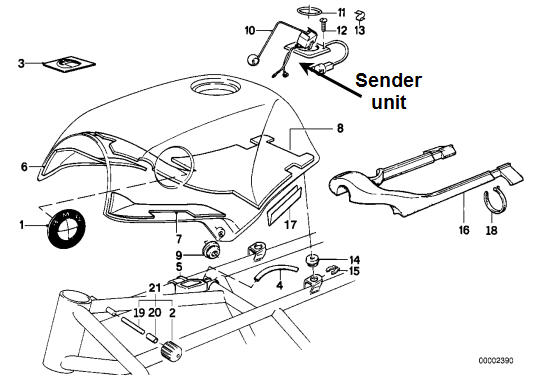

The latest K bikes fuel sender unit

can accommodate the installation of a fuel level gauge

Testing

the float arm sender Unit

(by RobMack)

Testing

the float arm sender Unit

(by RobMack)

I had a chance to look at my failing

fuel level sender today and discovered information that would be useful

for the community.

How does it work:

The sender has a movable arm ending in a float that

raises and lowers according to the fuel level. The arm articulates a

pair of metal wipers over two circuit cards.

The assembly is housed in a metal box welded to a bracket that mounts to

the bottom of the tank. The wiring goes through a liquid-tight

connector assembly.

Fuel Level Sensing:

The upper wiper sweeps across a 130 ohm wire wound

resistor plate, one end of which is connected to the liquid-tight

connector and the other end is not connected to anything.

The lower wiper sweeps across another plate containing two circular

contacts, one of which is wired to the liquid-tight connector, the other

is not connected at all.

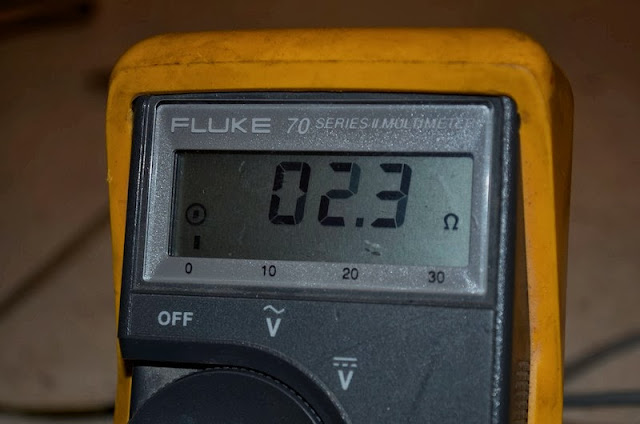

The upper wiper outputs a resistance value between 2 and 130 ohms,

proportional to the position of the wiper.

When the tank is full of fuel, the float is in its highest position and

the resistance measured should be around 2 ohms.

When the tank is nearly empty, the float is at its lowest position and

the resistance measured should be around 130 ohms.

To test the resistive wire, use a multimeter with

resistance measuring capability.

As in the photo set below, when measuring between the connector and the

left side of the resistor, the value should be around 130 ohms.

When measuring between the connector and right side of the resistor, the value should be around 2 ohms.

Reserve level Sensing:

The lower wiper outputs a binary signal

-- open circuit or grounded -- that communicates the reserve volume to

the low fuel light on the instrument cluster.

Normally, when the tank is full of fuel, the circuit is open. When the

arm reaches a certain position, the wiper contacts the conductor and the

output gets grounded.

This signals when the float reached the reserve position and the

instrument light should illuminate.

To test, , use a multimeter with resistance measuring capability. As in

the photo set below, there should be conductivity between the connector

and the left side plate.

There should be no conductivity between that same conductor and the right side plate.

How to Recondition the Sender:

The sender tends to fail because years

of accumulated corrosion prevents conductivity. The symptom of corrosion

will be erratic resistance readings from the upper wiper.

In the photo below, note the thick brown corrosion on the pivot hole and

green corrosion on the float arm pivot.

All this corrosion prevents an accurate resistance measure being sent to

the fuel gauge.

To recondition a failing sender, it is necessary to open the metal box

and clean the contacts.

There are four tabs that hold the case

closed. Carefully bend the tabs straight and the top will separate.

Be careful because there is a spring under the wiper arm and it may

fly off.

Remove the wiper arm and check that the contact pads look clean and shiny.

Depending on the age of the sender and

other factors, it may take no more than some Deoxit cleaner and a cotton

swab to clean the corrosion from the wires.

I would try this first. If the Deoxit doesn't get rid of the

accumulated corrosion, resort to a mildly abrasive paper.

Using a small piece of 1200 grit wet and dry sandpaper, carefully clean

the resistive wires of accumulated corrosion.

The technique is to fold a tiny piece in half so that is has some

stiffness and careful drag it across the wires IN THE SAME DIRECTION

AS THE WIRES ARE WOUND.

I use emphasis because you don't want to drag the abrasive paper across

the wires as it may break them.

Don't use any more pressure than is offered by the stiffness of the

sandpaper, such as pressing with your finger. The wire used is very

brittle and can easily break.

Using the same 1200 grit wet and dry, clean in and around both pivot

holes as well as the float arm pivots.

It is important to clean all corrosion from the pivots as from the hub

where the wiper blades are fixed.

The spring is there to act as a conductor, to allow electricity to flow

through the wipers, through the spring, through the pivots to ground.

This is the critical area where corrosion buildup will break the

sender. Once all corrosion is removed, reassemble the parts.

Test whether the cleaning is successful

by measuring the resistance over the entire sweep of the float arm.

The ohm meter should read consistent increasing resistance as the arm

moves from full limit to empty limit.

Reserve Level Adjusting

The point where the low fuel light

illuminates is dependent on the point during the rotation of the lower

wiper when it encounters the contact plate.

There is an adjustment on the sender which can determine when the lower

wiper contacts the plate.

In the photo above, you can see a

toothed wheel. This wheel rotates on a nylon pivot, causing the bottom

plate to be rotated and the contact to change position.

Using a small screwdriver, get a purchase on either of the indicated

lever points and engage the tip of the screwdriver's blade with one of

the teeth of the wheel.

Rotate the wheel with a levering

action.

* Rotating the wheel CLOCKWISE will cause the wiper to contact earlier,

resulting in a LARGER reserve volume.

*Rotating the wheel COUNTER CLOCKWISE will cause the wiper to contact

later, resulting in a SMALLER reserve volume.