Some while back, I had a

fuel sending unit on my K100 fail on me. It would not

register the volume at all. I had a chance to look at the

failing fuel level sender and discovered information that

would be useful for the community.

How does

the fuel sender work:

The sender has a movable arm ending in a float that raises

and lowers according to the fuel level. The arm articulates

a pair of metal wipers over two circuit cards. The assembly

is housed in a metal box welded to a bracket that mounts to

the bottom of the tank. The wiring goes through a

liquid-tight connector assembly.

Fuel

Level Sensing:

The float assembly arm has two electrical wipers attached to

it. The upper wiper sweeps across a 130 ohm wire wound

resistor plate, one end of which is connected to the

liquid-tight connector and the other end is not connected to

anything. The upper wiper outputs a variable resistance

value between 2 and 130 ohms, proportional to the position

of the wiper.

When the tank is full of fuel, the float is in its highest

position and the resistance measured should be around 2

ohms. When the tank is nearly empty, the float is at its

lowest position and the resistance measured should be around

130 ohms.

NOTE The fuel sender works in reverse to most modern motorcycle fuel senders, making it incompatible with many aftermarket gauges. This behaviour can be changed and will be described in a section below

How to

Test the Fuel Level Sensing:

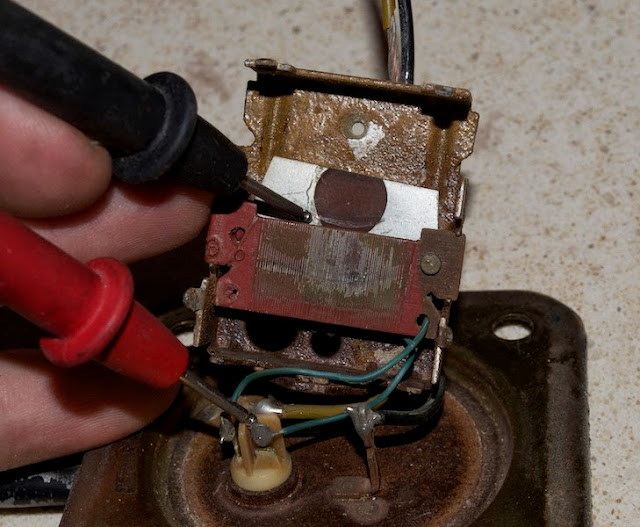

To test the resistive wire, use a multimeter with resistance

measuring capability. As in the photo set below, when

measuring between the connector and the left side of the

resistor, the value should be around 130 ohms.

When measuring between the connector and right side of the

resistor, the value should be around 2 ohms.

How to

Recondition a Failing Sender:

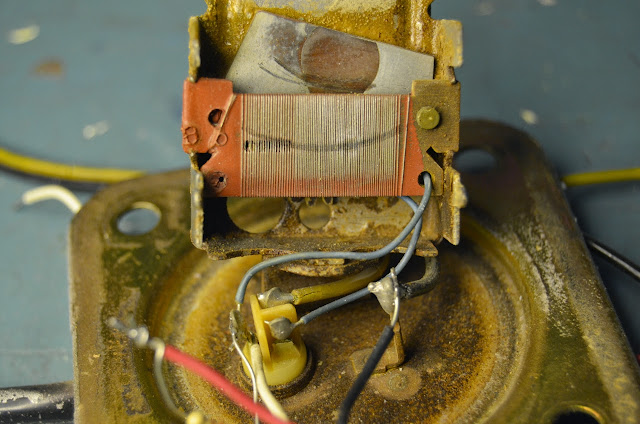

The sender tends to fail because years of accumulated

corrosion prevents electrical conductivity. The symptom of

corrosion will be erratic resistance readings from the upper

wiper and, most obviously, the fuel gauge will not register

anything on its display. In the photo below, note the thick

brown corrosion on the pivot hole and green corrosion on the

float arm pivot. All this corrosion prevents an accurate

resistance measure being sent to the fuel gauge. To

recondition a failing sender, it is necessary to open the

metal box and clean the contacts.

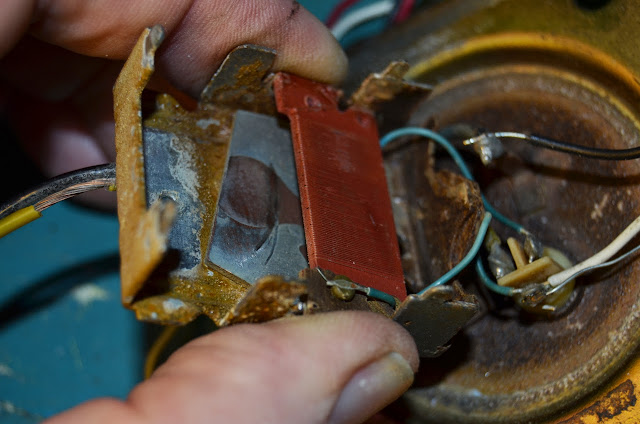

There are four tabs that hold the case closed. Carefully

bend the tabs straight and the top will separate. Be

careful because there is a spring under the wiper arm and it

may fly off.

Remove the wiper arm and check that the contact pads look

clean and shiny.

Depending on the age of the sender and other factors, it may

take no more than some Deoxit cleaner and a cotton swab to

clean the corrosion from the wires. I would try this first.

If the Deoxit doesn't get rid of the accumulated corrosion,

resort to a mildly abrasive paper. Using a small piece of

1200 grit wet and dry sandpaper, carefully clean the

resistive wires of accumulated corrosion. The technique is

to fold a tiny piece in half so that is has some stiffness

and careful drag it across the wires IN THE SAME DIRECTION

AS THE WIRES ARE WOUND. I use emphasis because you don't

want to drag the abrasive paper across the wires as it may

break them. Don't use any more pressure than is offered by

the stiffness of the sandpaper, such as pressing with your

finger. The wire used is very brittle and can easily break.

Using the same 1200 grit wet and dry, clean in and around

both pivot holes as well as the float arm pivots. It is

important to clean all corrosion from the pivots as from the

hub where the wiper blades are fixed. The spring is there

to act as a conductor, to allow electricity to flow through

the wipers, through the spring, through the pivots to

ground. This is the critical area where corrosion buildup

will break the sender. Once all corrosion is removed,

reassemble the parts.

Test whether the cleaning is successful by measuring the

resistance over the entire sweep of the float arm. The ohm

meter should read consistent increasing resistance as the

arm moves from full limit to empty limit.

Reserve

level Sensing:

The lower wiper on the float assembly arm sweeps across

another plate containing two circular contacts, one of which

is wired to the liquid-tight connector, the other is not

connected at all. The lower wiper outputs a binary signal

-- open circuit or grounded -- that communicates the reserve

volume to the low fuel light on the instrument cluster.

Normally, when the tank is full of fuel, the circuit is

open. When the arm reaches a certain position, the wiper

contacts the conductor and the output gets grounded. This

signals when the float reached the reserve position and the

instrument light should illuminate.

Testing

the Fuel Reserve:

To test, , use a multimeter with resistance measuring

capability. As in the photo set below, there should be

conductivity between the connector and the left side

plate.

There should be no conductivity between that same conductor

and the right side plate.

How to

Adjust the Reserve Level

Many people would think that one would have to bend the

float assembly arm to adjust the level of fuel where the

reserve light illuminates. Not so with the BMW fuel sender.

It has a built-in adjustment. The point where the low fuel

light illuminates is dependent on the point during the

rotation of the lower wiper when it encounters the contact

plate. There is an adjustment on the sender which can

determine when the lower wiper contacts the plate.

In the photo above, you can see a toothed wheel. This wheel

rotates on a nylon pivot, causing the bottom plate to be

rotated and the contact to change position. Using a small

screwdriver, get a purchase on either of the indicated lever

points and engage the tip of the screwdriver's blade with

one of the teeth of the wheel. Rotate the wheel with a

levering action.

-

Rotating the wheel CLOCKWISE will cause the wiper to contact earlier, resulting in a LARGER reserve volume.

-

Rotating the wheel COUNTERCLOCKWISE will cause the wiper to contact later, resulting in a SMALLER reserve volume.

How to

Modify the Fuel Sender to Make it Compatible with Modern

Gauges

As mentioned earlier, the fuel sender is incompatible with

modern gauges and aftermarket instrument clusters, like the

Koso, Dakota Digital and Acewell. It is a simple job to

modify the BMW fuel sender to make it fully compatible.

Disassemble the case by carefully straightening the four

tabs that hold the top with pliers until the top plate is

released.

Remove the top plate, float assembly arm and tension spring.

Be careful not to loose the spring nor damage the wipers on

the float arm. The resistor board will be revealed.

Locate the small tabs that secure the card to the frame.

These need to be moved out of the way to release the board

from the frame. I found that a set of slip-joint pliers

works best because they exert strong pressure and will not

slip. The tabs are very stiff so be careful not to bend

them too far nor break them. It will only be necessary to

bend the top two tabs a small amount to release their grip

on the resistor board.

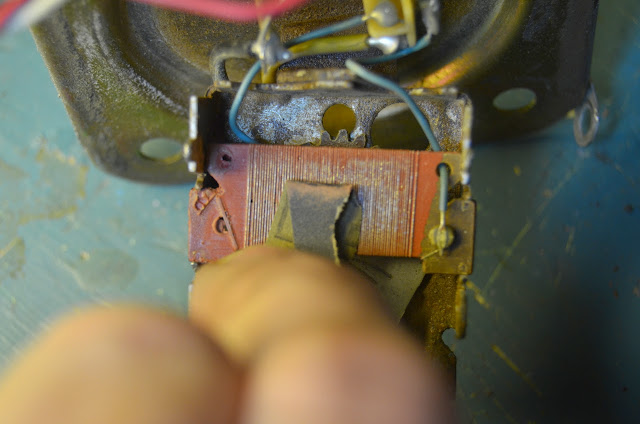

Once the board is freed from the frame, carefully remove it

and flip it 180° so that the obverse side is now facing up.

Reinsert it back into the frame and close the tabs to

secure the board. Try to handle the board by its edges so

as not to touch the resistive wires. The board only goes in

one way so it's not possible to incorrectly orient the

board.

I found that using a small drift and hammer worked very well

for closing the metal tabs. You'll want the board to be

fully seated in the frame.

Before reassembling the frame, it is necessary to remove the

enamel coating from the resistive wires. Be very careful

with this operation so as not to destroy the brittle wires.

Using a piece of 600 grit Wet-n-Dry, lightly sand the wires

ONLY in the direction they are wound. If possible use a

multimeter set on resistance mode to test that the coating

is fully removed and there is conductivity. If you skip

this step or do not remove all the coating, the fuel gauge

will not work.

It's also a good time to clean up any corrosion on the wiper

tips and pivot.

Reassemble the sender by reinserting the float assembly arm,

spring and top plate. Form back the tabs that secure the

top using slip-joint pliers.

Once this operation is complete, electrically test the

sender. Use a multimeter set on a range that can measure

resistance between 1 Ohm and 200 Ohms. Place one probe on

the frame and the other on the white wire. When you move

the float assembly arm, the resistance should change between

these values. You will find that the resistance will now be

about 2 Ohms with no fuel and about 130 Ohms with a full

tank. This range is directly compatible with modern

Japanese and European gauges. You might need to program the

gauge to understand the sender's range.