When should you replace the oil/water pump seals?

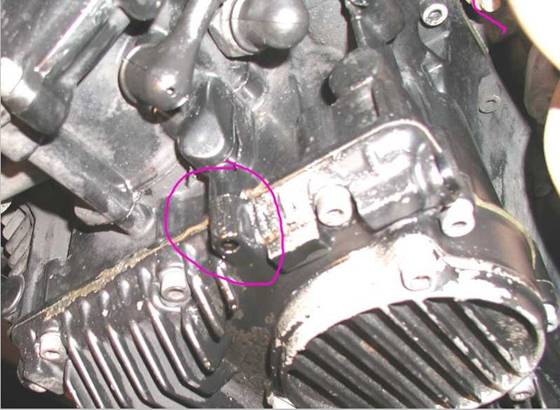

Most of the time, you will notice a small oil or water leak from the drain hole under the engine.

These pictures and procedures were posted by Meca-syl on the French forum

http://bmist.forumpro.fr

Thanks to him for the explanation and the hard work.

When should you replace the oil/water pump seals?

Most of the time, you will notice a small oil or water leak from the drain hole under the

engine.

First put the bike on the centre stand and lift the front wheel as

much as possible.

This is to avoid dumping all the oil when the pump will be removed.

You can empty the coolant by removing the drain plug under the

water pump,

but it’s faster to remove the water hose from the pump.

Remove all the screws on the covers. If needed, pry it open with a screwdriver.

Unplug the 2 wires for the oil pressure switch

and water temperature.

Pull them from the hole on the water pump and tie them on the side of the

engine.

Remove the

7 screws

holding the pump.

Put a container under the pump to catch the oil.

If the pump doesn’t come, hit it with a rubber mallet.

Be sure that the 7 screws are removed

The pump is now removed, and because of the front wheel

being

lifted, you will lose only the equivalent of a glass of oil

Now the pump

is on your bench and it’s time to put it apart

You will need a 13mm spanner on the turbine side and an allen key on the shaft.

The first generation of pumps didn’t have a spacer on the turbine.

When the turbine is removed, it’s time to push the shaft out.

Replace the screw on the shaft, then hit it with a mallet.

Remove the screw then pull the shaft out

The next step is to remove both seals (oil & water)

A small 90 degrees pry bar works well. If you use a screw driver,

be careful not to damage the bore where the seal goes in.

Turn the pump upside down and get a long nail.

Use the nail to extract the seals. First the water seal then the oil seal.

After many years, they may be stocked and you may have to use some brute force

to extract them.

Try to tap evenly on different points to avoid pushing it sideway.

Now comes the most annoying job: Cleaning:

The final result should look like this.

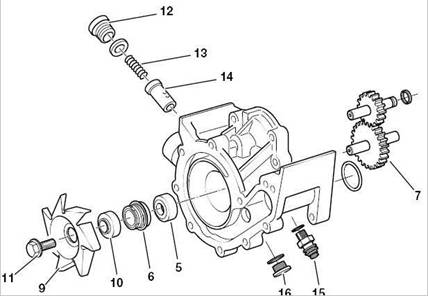

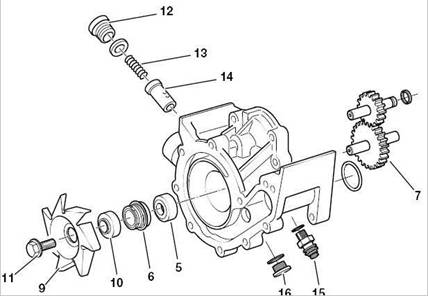

The repair kit contains the following:

1 8mm screw, 1 shaft, one turbine (The older model of turbines (die cast) cannot

be re-installed

with the latest generation of seals), 1 O ring, one spacer (The old one cannot

be re-installed with

latest type of seal), 1 mechanical seal for the water (latest generation), 1

oil seal, and

1 red O ring.

Before jumping and trying to re-install the seal, take some time to

understand its principle:

If not, you take some good chances to brake it.

Part of this new mechanical seal is made from ceramic discs making it very

fragile.

To insert the oil seal, grease it and push it in place. Take an

18mm socket and tap it with a mallet.

The water seal is inserted the same way as the oil seal but using a

27mm socket.

The blue paint is there to insure a good sealing of the outside diameter.

When the 2 seals are replaced, re-insert the shaft (lightly oil it).

Push it gently until it stops. The shaft will not be totally in, but

DO NOT

FORCE OR HIT IT WITH A HAMMER

We will use a screw to gently pull it through the water seal.

To pull the shaft, we will use an 8mm threaded road, a nut and the

old spacer.

On the following picture, you can see the difference of thickness between the

new and old spacer.

The first generation of pumps didn’t have a spacer. Do not use the new spacer to

pull the shaft.

In stead, use a 19mm socket and a flat washer.

Screw the threaded rod onto the shaft, put the spacer (or the 19mm socket + the

washer), the nut

and pull the shaft until the gear comes flush with the casing.

If you pull the shaft beyond this point, you take the chance to break the

ceramic seal.

The other method is to use a flat bar to make you own puller (see

next pictures)

Install the new spacer then the turbine and torque the screw to 3.3kg/nm.

If you want you can put some Loctite on the thread.

Replace the O ring on the small pinion

Clean the engine and install the new red O Ring.

Install the small pinion. (Turn it until it gets into place)

Put some gasket sealer on the pump housing (Not too much near the gears), put

the pump in place turning it to match the teeth on the pinions.

Re-install the 7 screws and re-insert the wires for the water temperature sensor

and the oil pressure sensor.

Put some gasket sealer on the water pump cover,

re-install it

Install the water

hose and refill the system.

Don’t forget to check your oil level.