|

On a car, where the space is less restrictive, the starter

is composed of 2 major distinct components: the motor and the solenoid.

When current from the battery is applied to the solenoid (top part

of the starter), it pushes out the drive pinion out and the starter

driveshaft meshes the pinion with the ring gear on the flywheel of

the engine.

On most motorcycles, space restriction doesn’t

permit to fit a bulky starter with a solenoid. Manufacturers have adopted 2

other solutions: an electric motor in conjunction with a free wheel and/or a sprag clutch. This is not new as 40 years ago the English and Italian bike had

already fitted their electric starter with this system .

However, because of the physical layout of the cylinders leaving plenty of room

on the top of the engine, some bikes like the BMW R series (flat twins)

and Moto Guzzi (V twins) are fitted with a starter and solenoid.

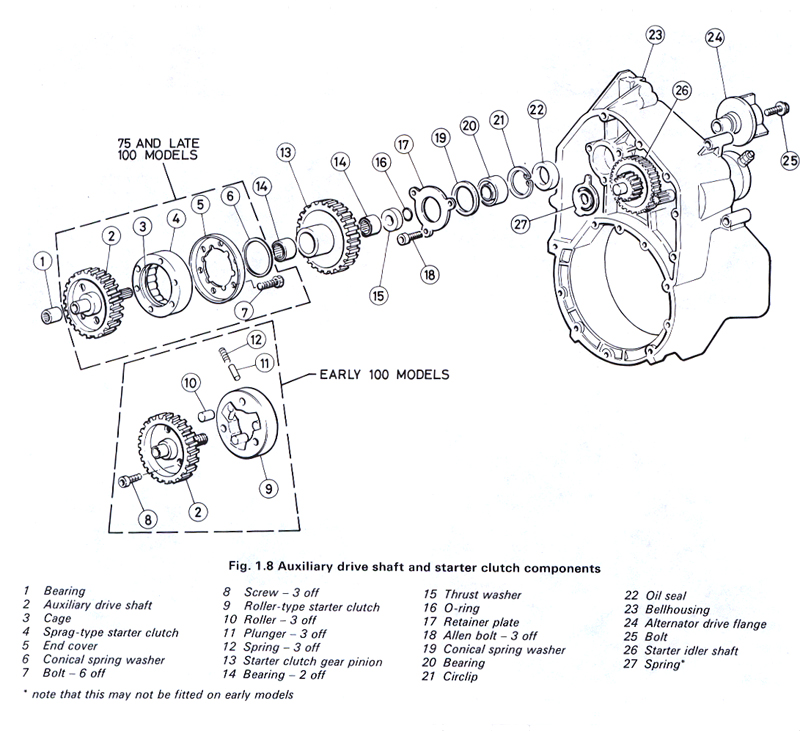

On the early K100 (1984), BMW used a free

wheel to drive the crankshaft from the starter. The free wheel had only 3

rollers and was quickly replaced in 1985 with a sprag clutch.

How did it work?

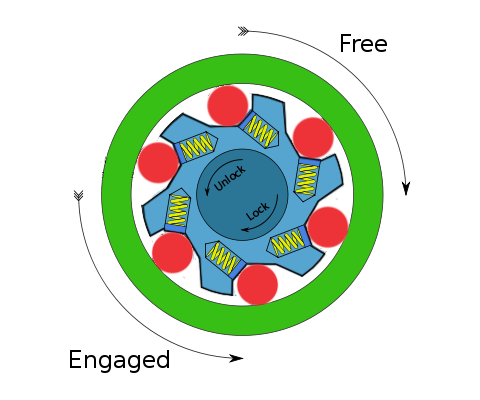

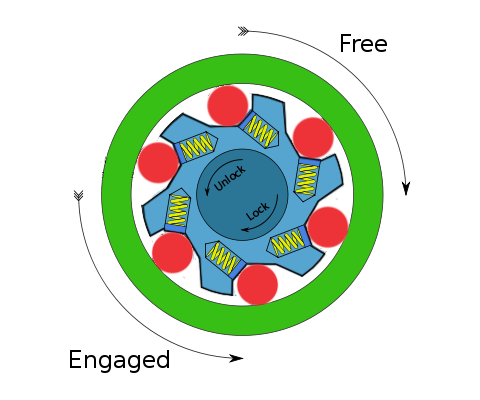

The small springs keep the rollers lightly in contact with the outer ring.

When the inner ring is rotating CW, the rollers are pushed against the slanted

ramps creating a binding between the inner and outer rings.

When turning CCW, the binding is released and the small springs will give just

enough pressure on the rollers to have them dragging against the outer ring but

not locking the 2 rings together.

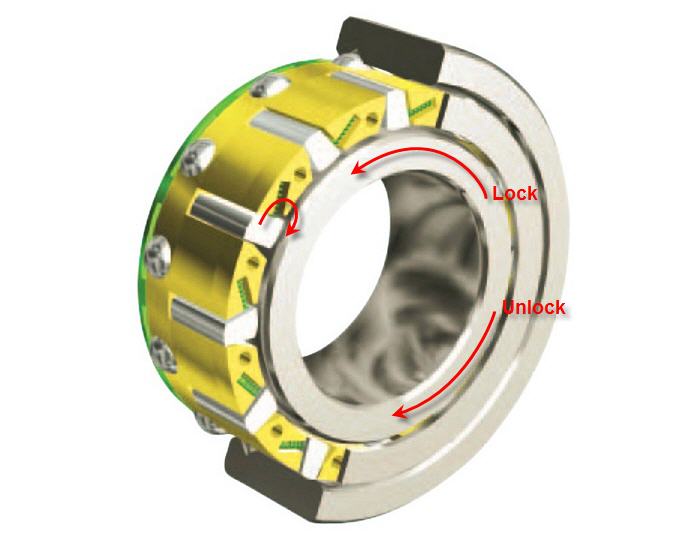

From 1985 on, BMW adopted another solution for the K100: the sprag

clutch.

What is a sprag?

The English dictionary defines it as a piece of wood or metal wedged

beneath a wheel or between spokes to keep a vehicle from rolling.

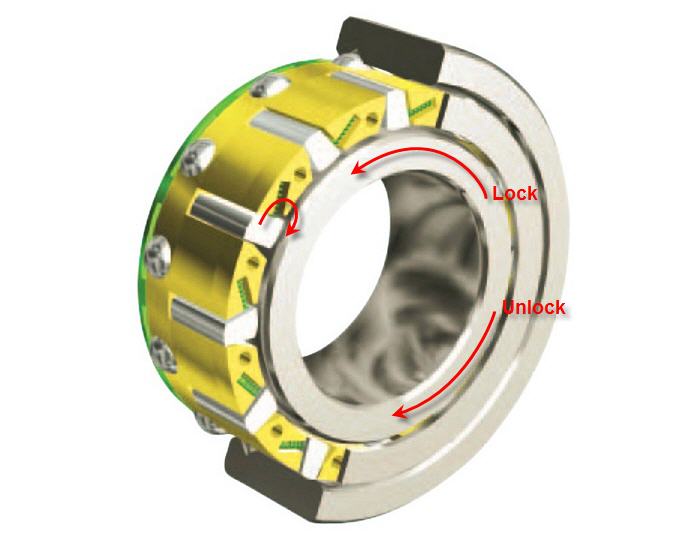

The sprag clutch is working on the same principle as the free wheel (friction

and binding) but in stead of rollers, it uses metal wedges. When the inner race

is turning CCW, it will drag and tilt the sprags and subsequently lock the inner

and outer races together.

The starter is not mounted on the sprag clutch. A set of intermediate gears

reduce its speed and increase its torque. The intermediate gear is what is

driving the inner ring of the sprag clutch. The outer race is linked to the

crankshaft.

When the outer race (crankshaft) is turning at a higher rpm than the inner one

(starter), the pressure on the sprags is released. The small springs are keeping

enough pressure on the sprags to have them dragging on the inner race.

Here is a very comprehensive animation of

a sprag clutch (Springs are not represented on this animation).

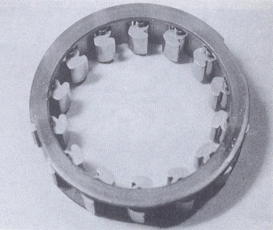

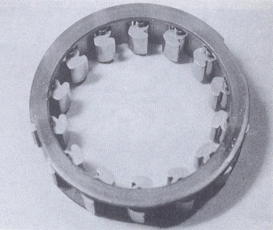

And here is the actual sprag clutch of

the 1985 K100.

In order to keep a permanent contact between

the inner and outer race, the BMW sprag clutch is fitted with small springs (not

visible on the previous picture) applying a small constant pressure as

illustrated on the following diagram. (This is just an illustration to show the

principle.)

A dirty system will prevent the sprags or

springs to move freely and consequently render the system inefficient. The

clutch will start to work erratically and the starter will spin without driving

the crankshaft.

On the K engine, the sprag clutch is lubricated by the engine oil. The carbon

deposit is what gum this clutch. In order to access and clean the sprag clutch,

removal of the transmission, clutch and bell housing will be needed.

One solution found by many riders is to flush the

engine to try to get rid of the sludge. Some people found that running the engine with

good quality diesel engine oil will dislodge the sludge and solve the problem. 88 from the k100-forum found another good solution:

With the right side (crank cover) off you can access

the oilway holes in the sprag clutch. Turn the engine over gently

you line it up where you can get a shot of cleaning oil in there.

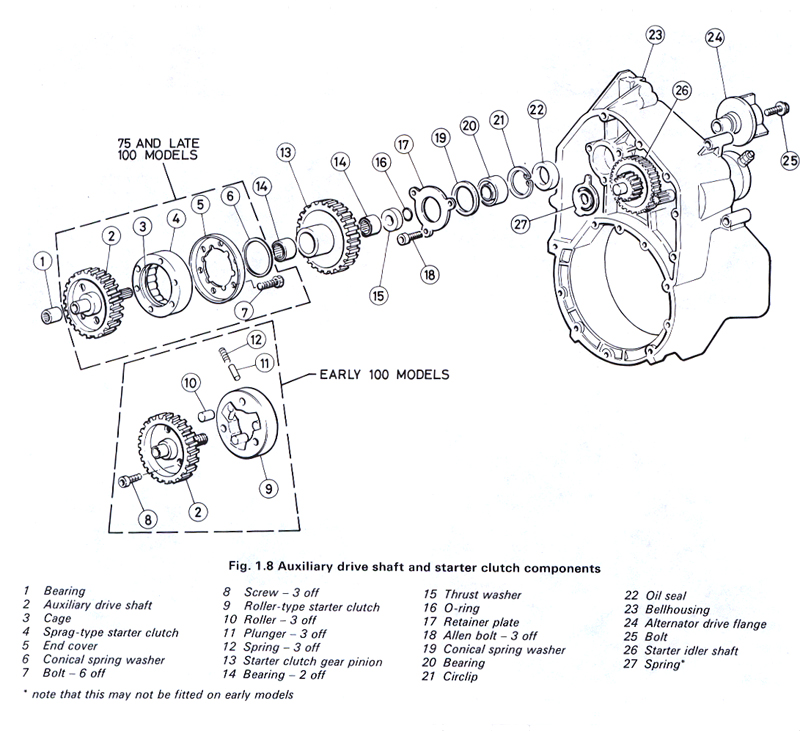

On the following picture (BMW K100), #5 is the sprag clutch. It is driven from

the starter motor with intermediate gears #13 and #26.

Hope this will help you to understand the link between the sprag clutch and the

crankshaft.

Bert.

|