|

It's a nice day and you take your

K100 for a

long ride. Everything is fine and a the end of the day you park the bike in the

garage.

Next morning, you want to take it to go

to work and...... it doesn't start!

Where do you start to troubleshoot?

_________________________________________________________

|

This document should help you to understand how the LE-Jetronic

and the electronic ignition are working.

I would happily add your comments and experience to this

page if they are relevant.

This page is a guide and not a reference as I

am not a professional.

You don't

need electronic knowledge but basic electrical

knowledge

in order to test both units following the information on this page.

The following explanations and schematics are specific to

the early K100 2 valves.

The 4 valves RS is slightly different but the same principle

applies to it.

The K75 shares the same technology and other than an extra

coil, the electronic is similar.

|

|

First, you have done all the basic troubleshooting

such as: checking the fuses, ignition switch, kill switch, side stand

switch (not applicable on early K100), transmission in neutral,

clutch in, starter connection, Fuel pump connector on the fuel tank, and battery connections.

The ground connections are critical for the

electrical system. The ground connection between the battery (-) and the

side of the transmission should be cleaned and tested. the

connection #9 on the frame should also be checked. (Remove the

screw and clean all the connectors)

Most of the

starting failures are related to a corroded ground connector! |

|

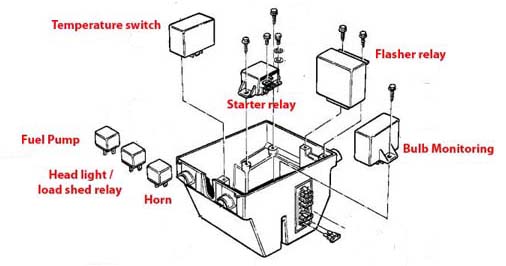

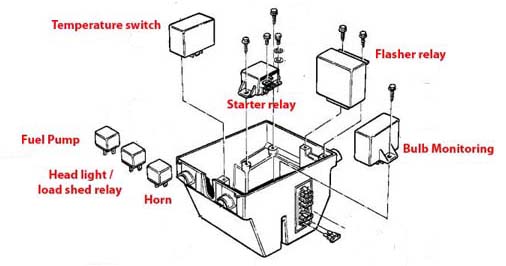

First, here is a

couple of schematics showing the location of the electrical

components:

|

|

Under tank

connectors and ground

|

Fuse box

|

|

Layout of fuses on the

electrical diagrams

Layout of fuses on the bike

| Fuse # on the bike |

Fuse # on the

diagram |

Value |

From |

To |

| 1(top) |

2 |

7.5A |

FI relay, Kill switch |

Stop light, Bulb monitoring, accessory

socket |

| 2 |

3 |

7.5A |

Parking Light |

Bulb monitoring |

| 3 |

4 |

15A |

Battery + |

Flasher unit, clock |

| 4 |

7 |

15A |

Battery + |

Unused |

| 5 |

5 |

15A |

Battery + |

Alarm, light socket |

| 6 |

6 |

7.5A |

FI relay |

Temperature unit, Fuel pump |

| 7 |

1(top) |

15A |

Load shed relay |

Flasher unit, horn relay, alarm socket |

|

|

Electrical components in the tray under the tank.

|

|

|

__________________________________________________________

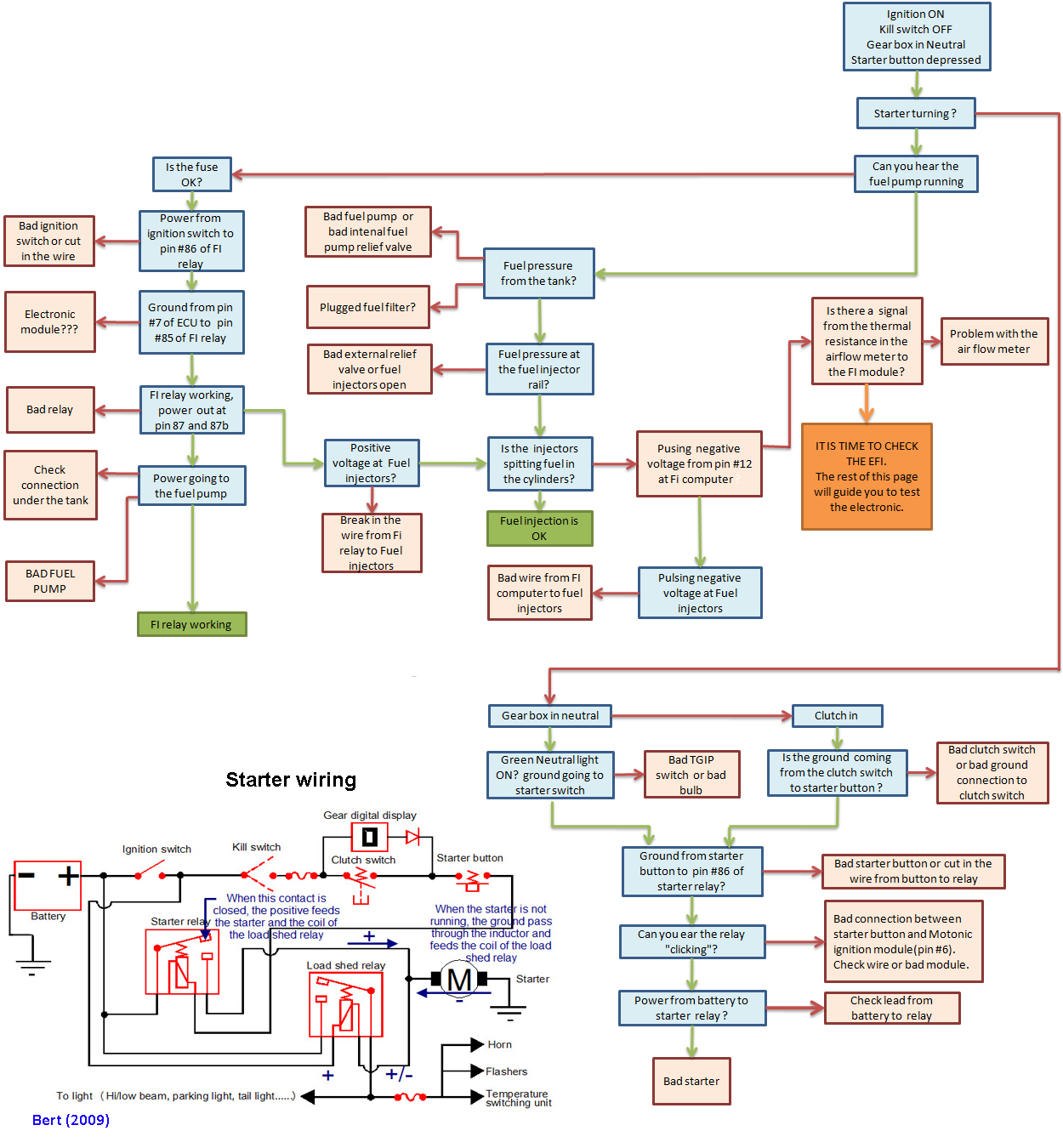

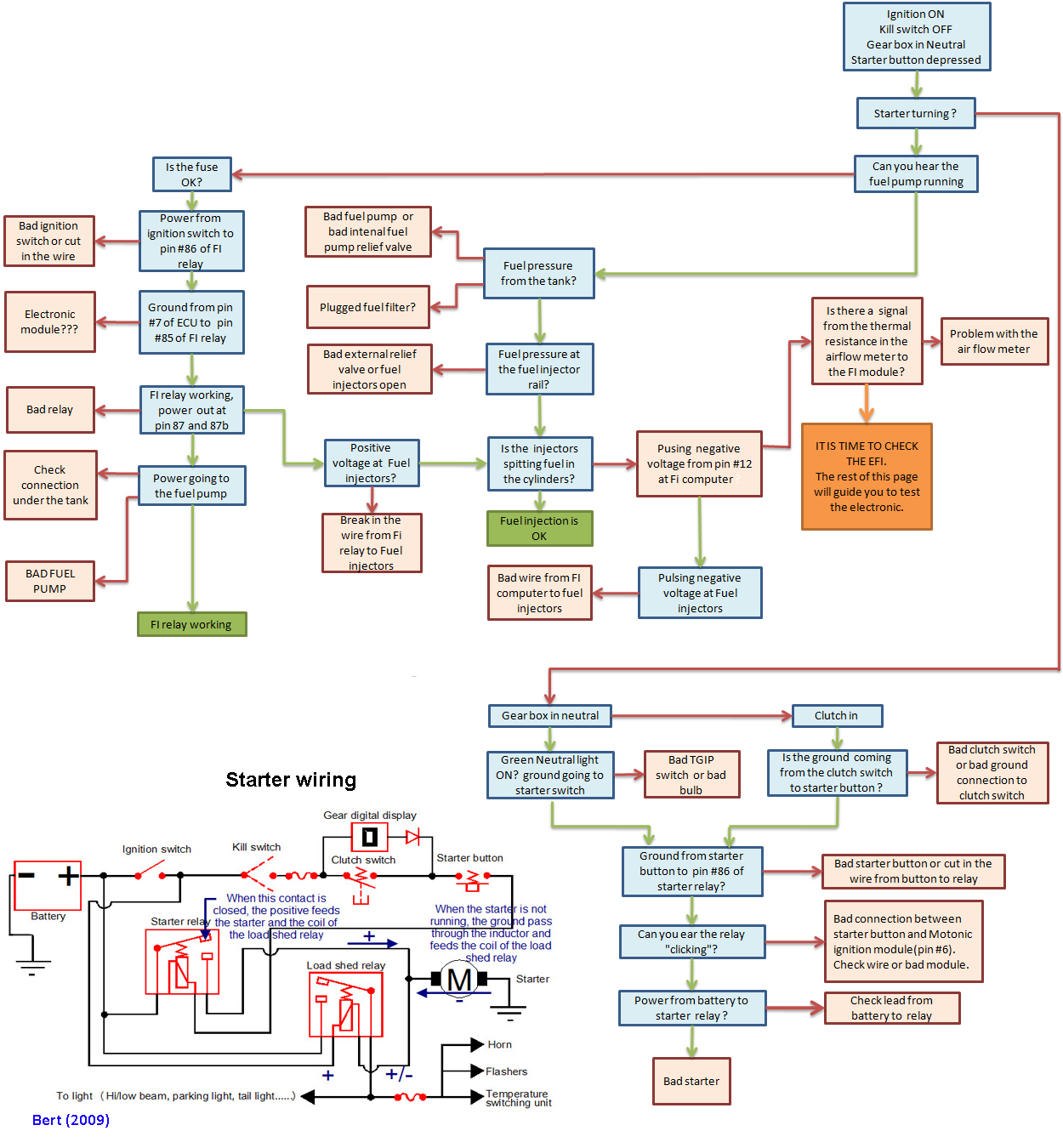

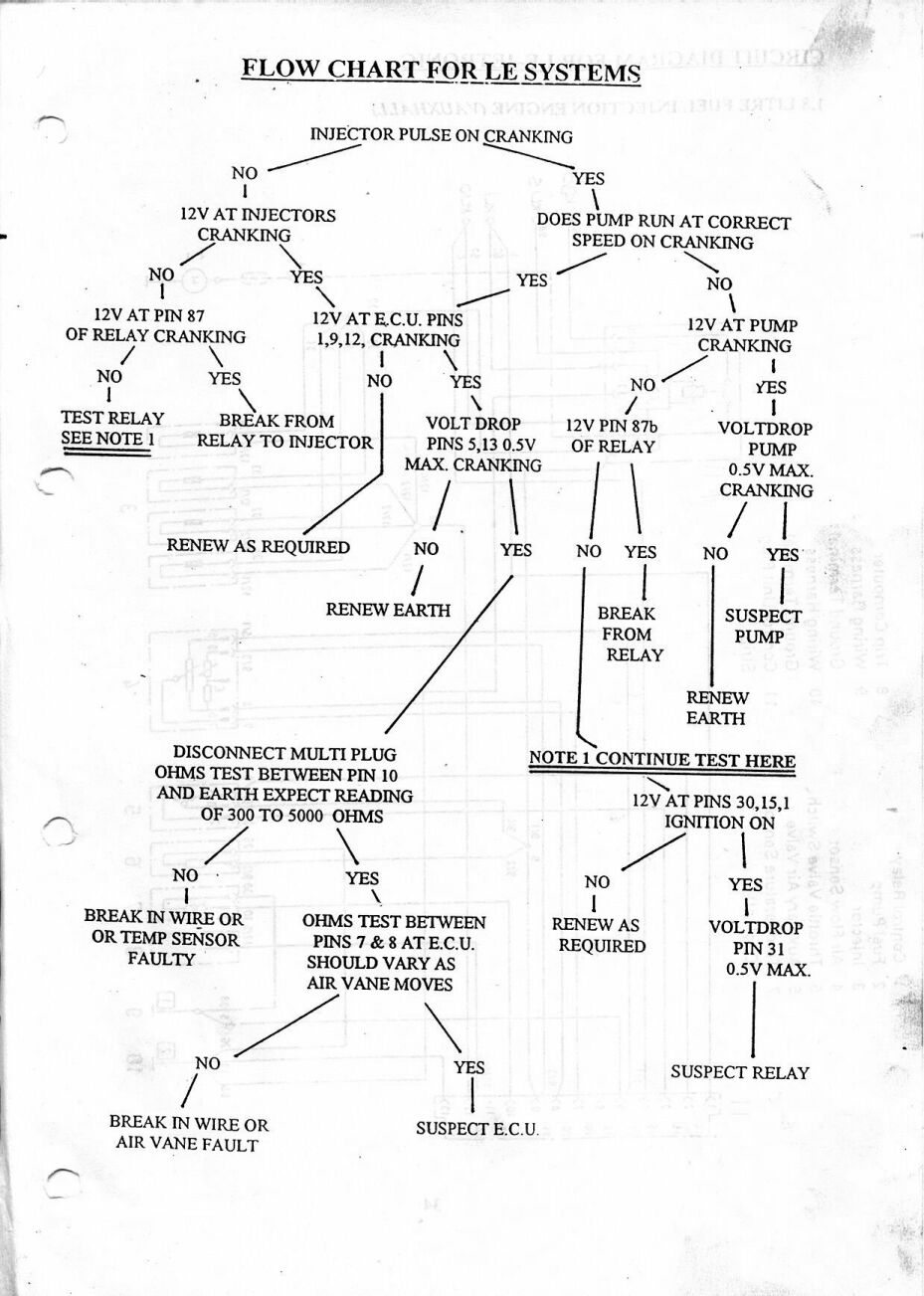

Is your problem the ignition or the Fuel Injection?

When the engine doesn't start, you could use this method to start

the troubleshooting.

To quickly control if the ignition is working, use an induction

strobe light on the sparkplug wire.

|

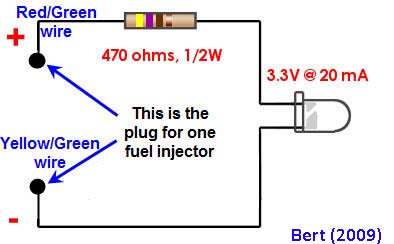

To quickly control if the FI is working, plug an LED into one of the

fuel injector connector.(see notes at the bottom of this page)

|

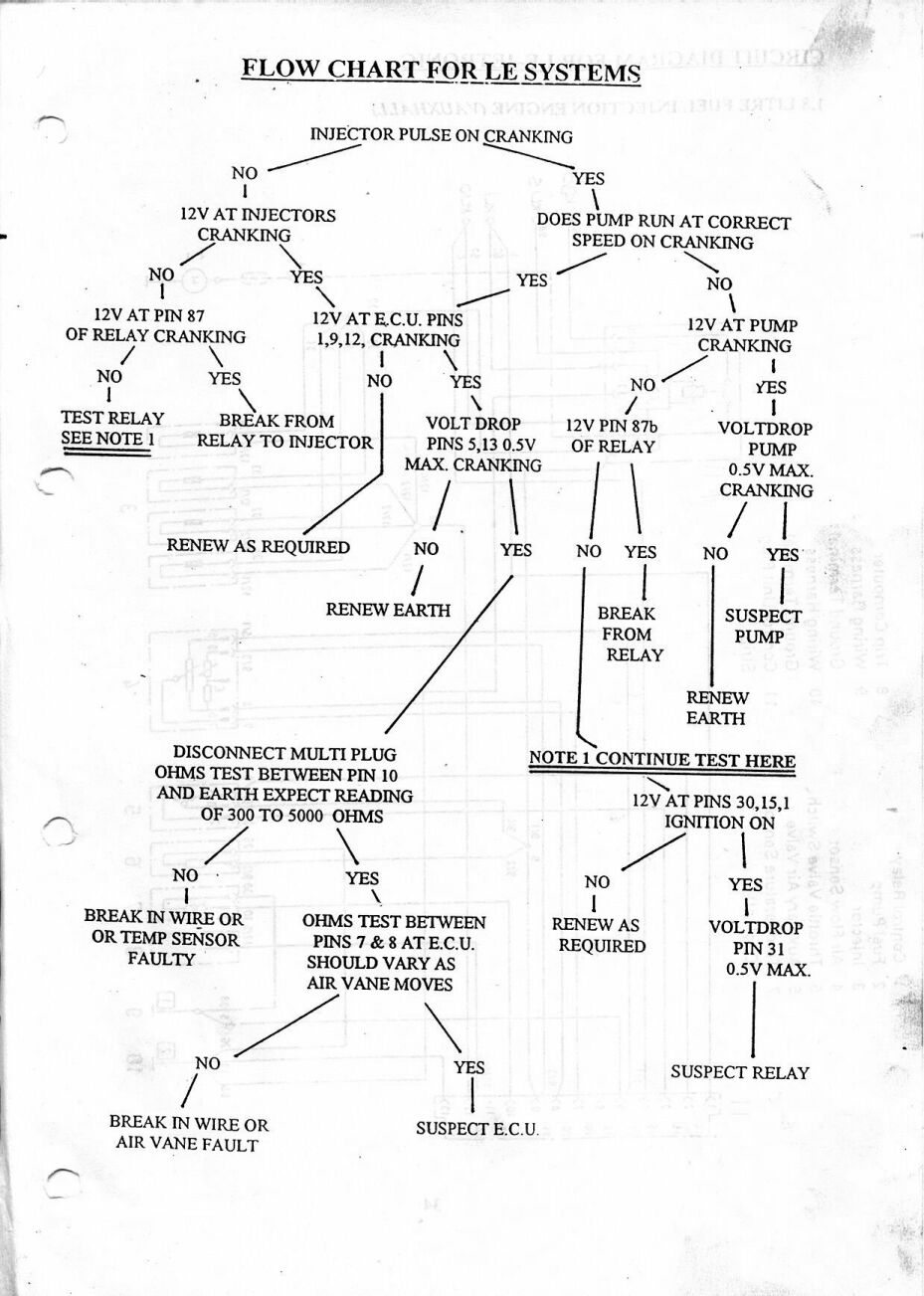

If the ignition is working, follow this troubleshooting chart to try isolating the problem.

If you have reached the orange box, it's time to take measurements at the FI computer connector.

Just continue reading the rest of the page.

Here is another flow chart:

The result of your investigation

points to the EFI system.

How does it work?

How does it work?

You may not be an electronic engineer, but after reading the remaining

of this document you should have a pretty good knowledge of the system.

Basic components and functions of the

EFI system:

2 major factors influence the EFI computer: Air flow detected by the air flow

meter and engine rpm detected by the HALL sensor

Other data collected by the EFI computer are: Air temperature, Water

temperature, Throttle switch position and Battery voltage

|

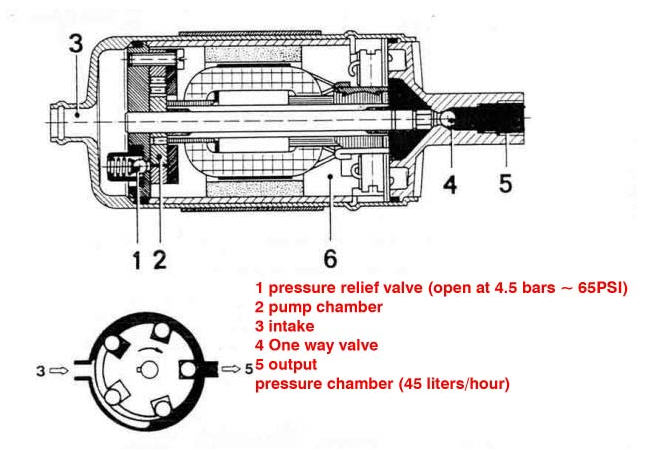

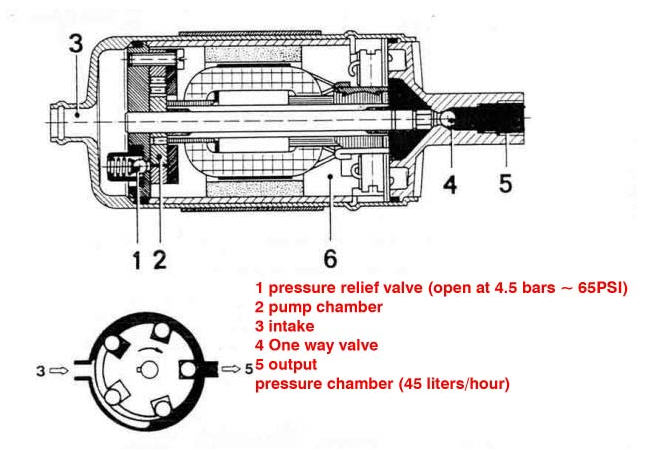

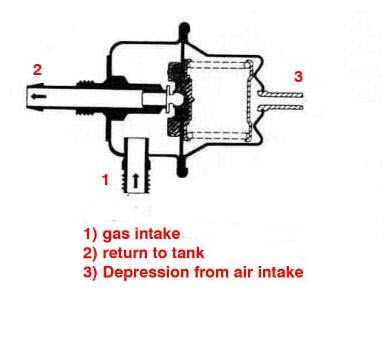

Fuel pump |

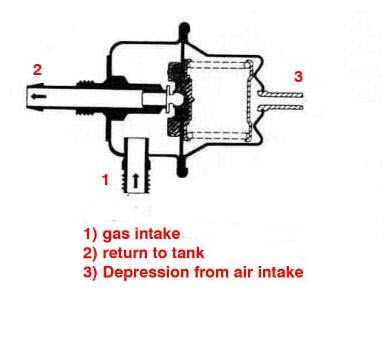

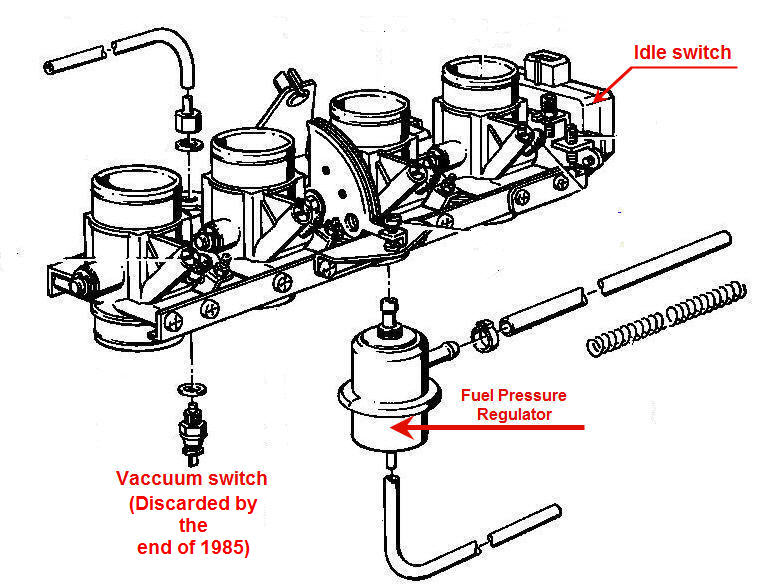

Fuel Pressure Regulator |

|

|

Fuel pressure is sent from the pump to the Fuel injector rail. The fuel pressure

regulator will keep a constant pressure into the fuel injector rail. The fuel

pressure regulator is located on the back of the fuel injection rail (not easy

to access) and its depression is collected at the intake manifold for cylinder

#4.

The fuel pump is delivering 65 PSI of pressure, and the pressure regulator drops it to 36PSI.

For information: you can find an aftermarket pressure

regulator at a cheaper price than at your favorite BMW

dealer:

Napa #2-1709A or Standard #PR-134 |

|

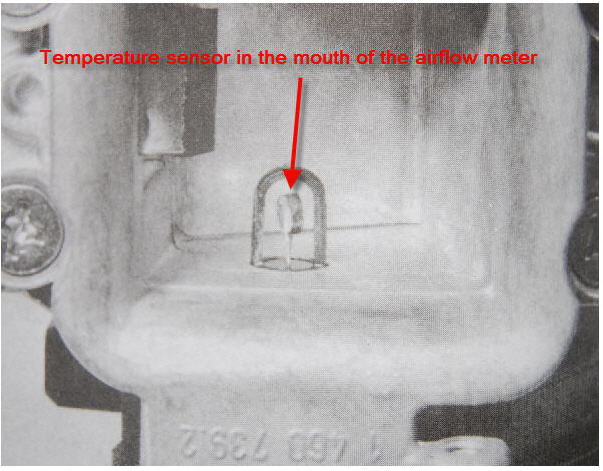

When the engine revs under

900rpm, the EFI computer doesn’t take into account all the

data collected by the air flow meter. It collects only the

air temperature and adjusts the fuel injection accordingly.

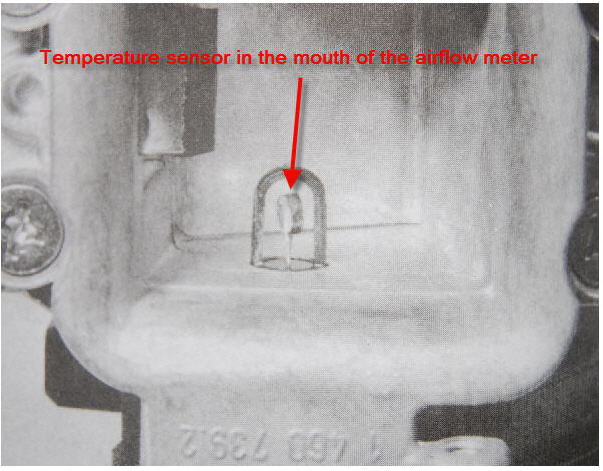

(The air temperature sensor is a small thermi-resistor

located in the mouth of the airflow meter).

|

|

|

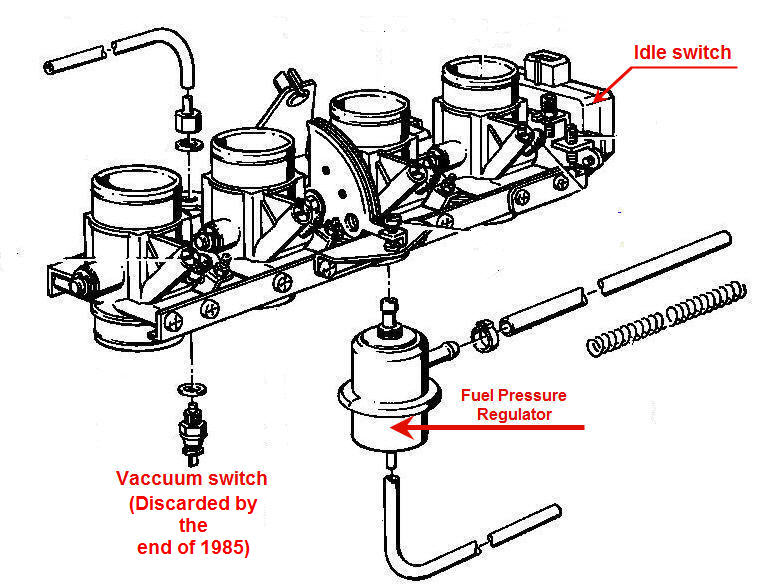

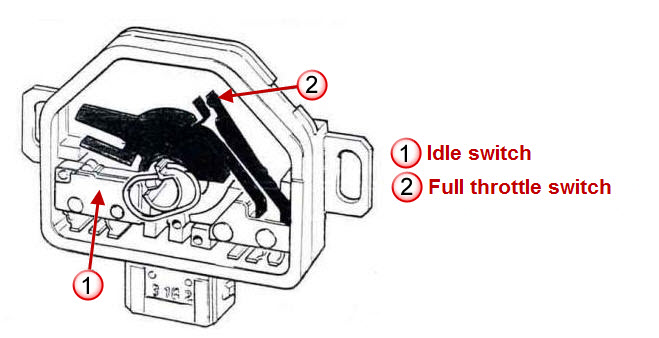

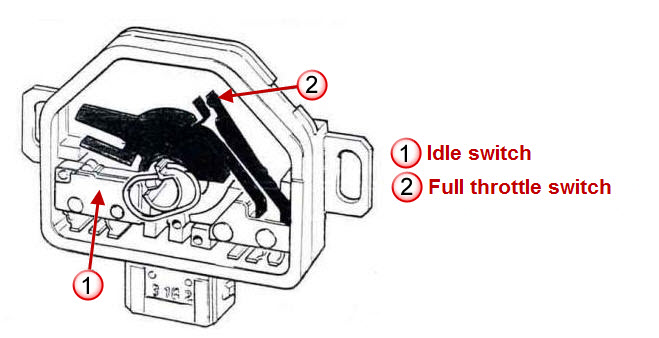

The idle switch (Also called butterfly switch

or throttle switch) is located at the end of the fuel

injector rail. It will cut-off the fuel injector when your

are releasing the throttle.

With this system, when decelerating (switch 1 close), the

fuel injection is disabled until the rpm goes down to

2000rpm. If the engine is still decelerating and the rpm is

lower than 2000, the EFI is re-enabled and the injection is

controlled again by the FI computer. As an

example, when riding at 5000rpm and cutting the throttle,

the injection will be cut off between 5000 and 2000rpm.

This switch assembly only signals idle or full throttle to

the EFI. Mid throttle signal to the EFI is controlled by the

vacuum switch.

(A good indication of a bad setup is when the engine

backfires when decelerating). When you twist the throttle,

the same switch (contact # 2) will tell the EFI computer

that the engine is on full load and the mixture

air/fuel will be enriched

IF the bike doesn't start and you suspect the fuel

injection, try to start the engine with this switch

disconnected. A bad switch may send a wrong signal to the EFI computer.

When this switch is disconnected, the EFI thinks that your

are twisting the throttle. |

|

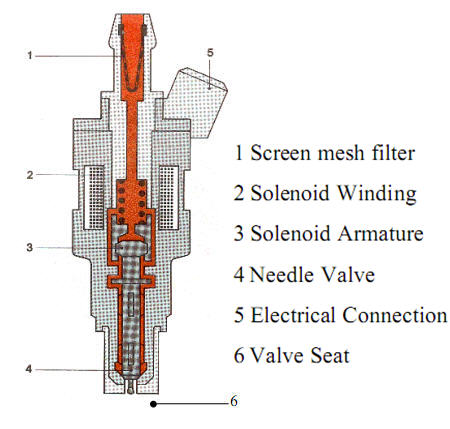

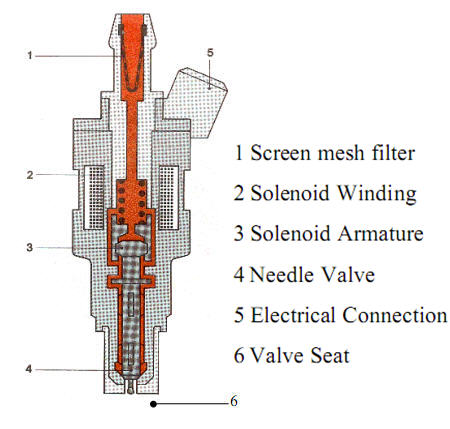

The 4 injectors all open and close at the same time when

commanded to do so by the ECU. It's important to understand

that the injectors do not really spray fuel, they are just

valves that open and close. They are needle valves that plug

a small hole when closed. They are opened by a tiny

electromagnet in each injector that pulls the needle away

from its hole enabling fuel to pass into the intake system.

When they are open fuel sprays in as a result of fuel

pressure, so

it's really the pump and fuel pressure regulator that

control how much fuel sprays in for a given amount of time

when injectors are open.

The ECU regulates how much fuel is sprayed in by controlling

the amount of time the injectors are open. Your ECU assumes

your bike has the correct amount of fuel pressure. If you

have more or less it will effect your ECU's calculations.

An injector can go bad in a number of ways. They

can have external leaks, internal leaks, fail to open, or

fail to close or be clogged with combustion debris. Symptoms

of a bad injector or injectors can include difficult or

impossible cold or warm starting, irregular idle, lack of

power, poor fuel economy, missing, high emissions and

external fuel leakage.

It's important to check the injectors internal

electrical coil. Remove the injector's electrical

connector and check the resistance between the injector's

terminals. It should be 16

Ω. If it's not you will have to buy a new injector because

there is no way to replace the coil.

If your injector is leaking internally or failing to

close fully the bike might run OK depending on just how bad

the problem is. The way to check for this problem is simple.

When you change spark plugs inspect them. If one or two are

a lot blacker then the others you probably have a leaking

injector on those cylinders.. If the leak is bad or the

injector never closes, the bike will run poorly at low RPM

but improve at high RPM when the engine is sucking in enough

air to burn the fuel.

The most common injector problem and the most

difficult to detect is the partially clogged or "dirty"

injector. Unfortunately there is no practical way to check

for this problem without pulling out the injectors so we

need to use the process of elimination. If you have checked

everything else out and your bike still has some running

problem then it's probably one or more dirty injectors.

Putting injector cleaner in the fuel tank will not clean the

injectors. To clean them they need to be pulled out and sent

to an injection shop. Most injection shops have a service

that will include ultrasonic cleaning, new tips and intake

screens for about $25-$35 dollars for each injector.

If you find one or more bad injector there is little

choice but to buy new ones. Let's get one thing clear, THERE

IS NO SUCH THING AS A REBUILT L-JETRONIC INJECTOR!

They can be cleaned, the fine intake screen can be replaced

and the ceramic tip can be replaced. That's it! The life

limiting component is the internal "O" ring and it can't be

changed. |

Injectors:

|

|

Airflow

meter:

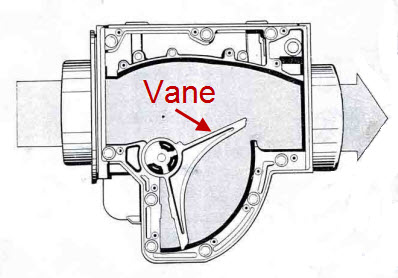

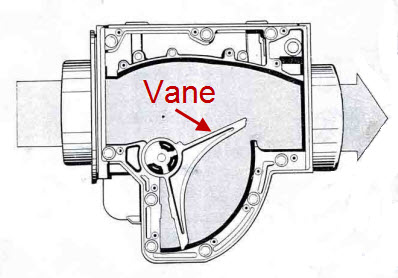

Air traverses the air filter and

goes to the air flow sensor. When you open the throttle, the

depression is moving the internal vane of the air flow meter

and a bigger amount of air is sucked in by the engine. The

movement of the vanes will turn a variable resistance. This

variable resistance will tell the EFI computer how much gas

it has to send to the injectors to balance the mixture air/fuel.

The volume of air drawn in by the engine

reflects the condition of the load. The precise measurement

of this parameter is essential to determine the exact volume

of fuel to inject.

The sensor plate adopts an angular position in relation to

the force applied to it by the air drawn in by the engine

Positioned in the damper chamber, the compensator flap (with

the same effective area as the sensor plate) reduces

pulsations due to any back pressure in the inlet manifold.

A temperature sensor is connected in parallel in the air

flow sensor electrical circuit. This is a thermiresistor.

Its resistance reduces as the temperature rises. It modifies

the output signal from the air flow sensor in relation to

the intake air temperature. Some air, not taken into account

by the sensor plate, pass through the by-pass.By altering the section of the by-pass, the idling

mixture can be altered.

The potentiometer, directly attached to the sensor plate,

transmits to the electronic control unit the voltage

corresponding to the angular position of the sensor plate.

It is assembled in dry conditions in a sealed casing, the

potentiometer consists of ceramic plate supporting a contact

strip and several resistors whose values have been adjusted

by laser beam.

These resistors have the special quality of not varying with

the sharp changes of temperature which occur in the engine

compartment. A cursor directly attached to the sensor plate

makes contact with the contact strip.

The battery voltage doesn’t influence the signal from the

potentiometer, it is the relationship between the

potentiometer signal and the battery voltage which is taken

into account by the electronic control unit.

The intake air temperature, measured by the temperature

sensor, has a direct effect on the voltage of the

potentiometer signal.

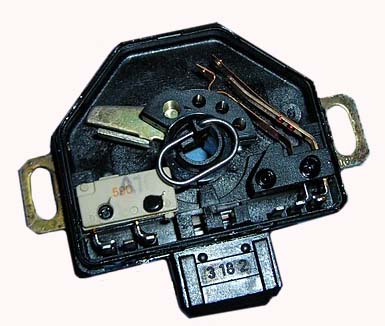

Here is what you will find when

opening an airflow meter. This one is defective and the

problem comes from pin #5

(The connection with the board is broken and doesn't

make contact with the circuit.)

|

|

The EFI computer is pre-programmed to get maximum optimization during startup.

As long as the starter switch is depressed, the EFI computer will enrich the

mixture air/fuel.

When the engine reaches 900rpm, the air

vane position is fed

to the EFI computer.

|

Now, let's get practical....

EFI

and Electronic ignition components.

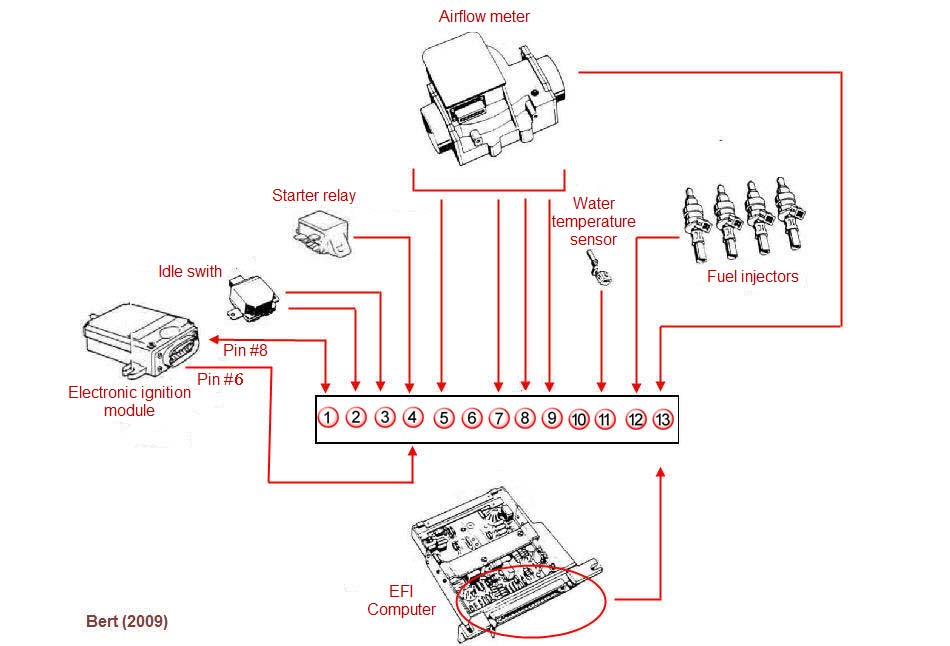

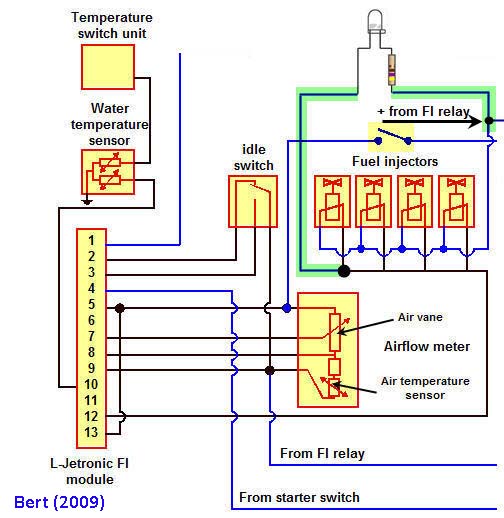

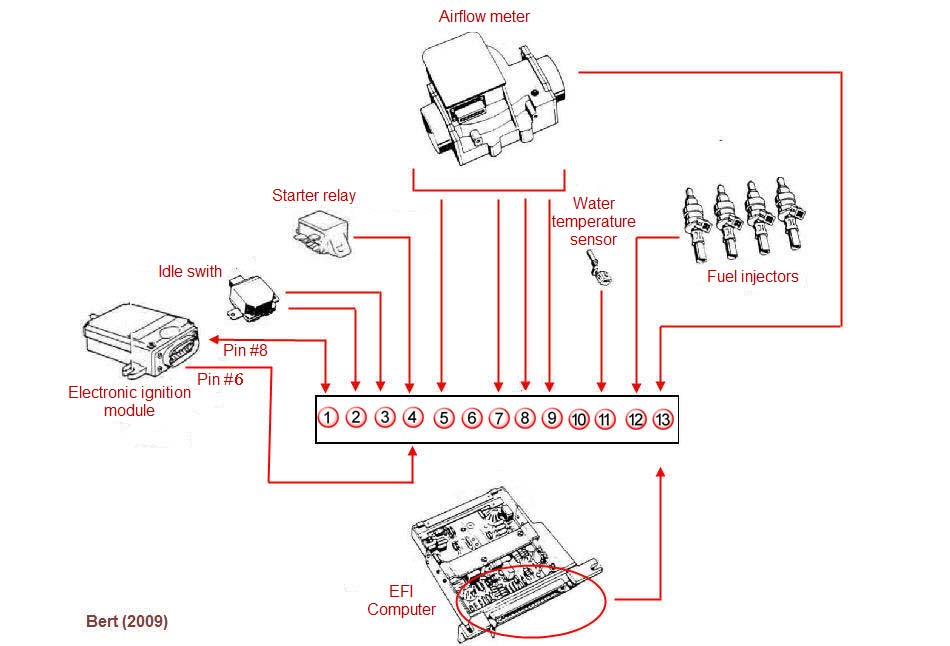

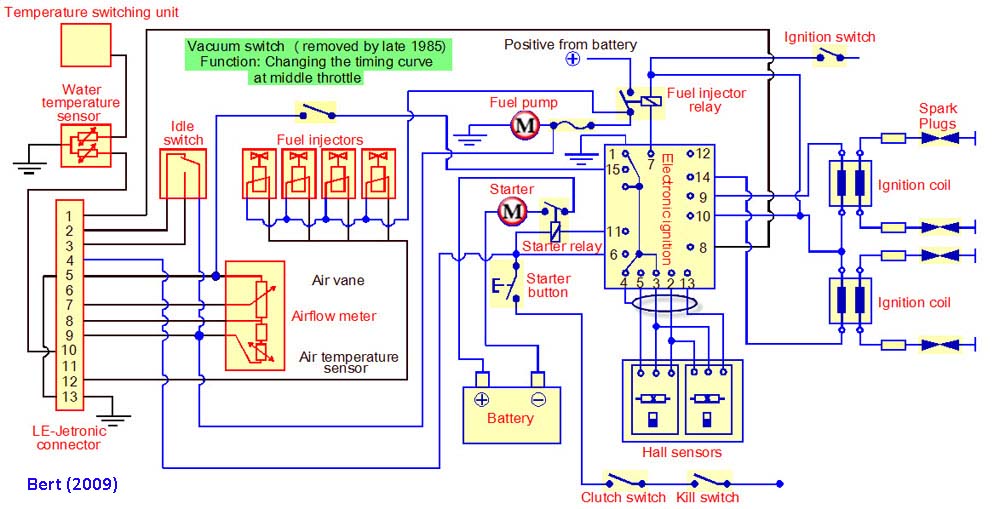

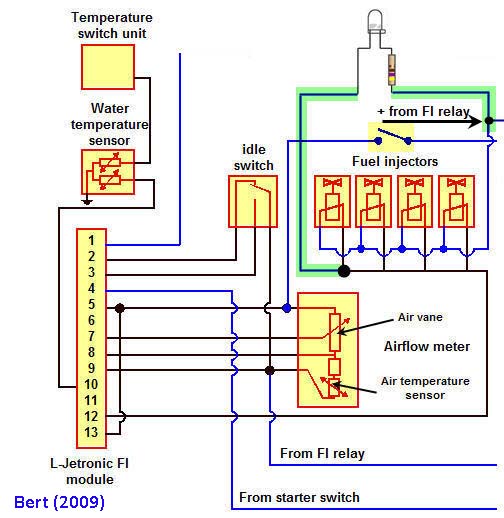

The following graphic shows the

different components and their connection to the EFI computer.

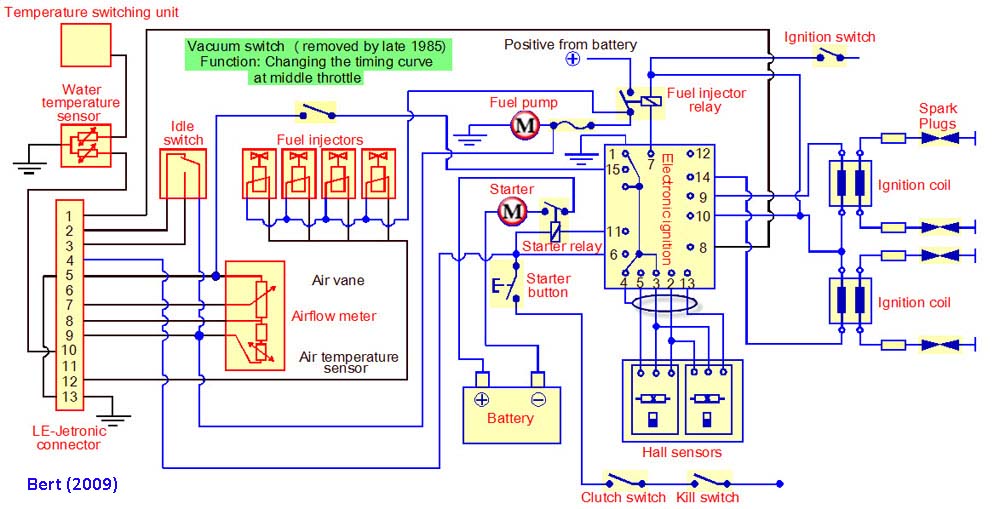

Here is the detailed wiring (EFI / ignition)

Or if you prefer, this simplified schematic of the wiring:

You can try to follow the full electrical wiring but this

is very confusing.

I have made an easy to follow electric color diagram:

The color interactive diagrams

is available by clicking here

Quick explanation of the principle:

|

What's happening when

you press the starter switch:

The starter relay and Fuel Injection

relay close, Hall sensors get power.

The FI relay

energizes (+) the fuel pump, the idle switch, the injectors and the air

flow meter.

The Jetronic receives (pin #4) the signal that the engine is starting

and it sets itself on starting mode (enriching the air/fuel mixture)

Electronic ignition module pin # 9-10-14 send power to the ignition coil

Electronic ignition module pin #8 send engine rpm info to pin #1 of FI computer

Electronic ignition module pin #7 send ground to the coil of the FI relay as soon as the

starter switch is depressed. The ground will stay on after the starter

switch is released as long as the Electronic ignition module receives a signal from the

Hall sensors.

Notes:

Under 1300rpm, the timing is set to 6 ̊. Then, the Electronic

ignition module will modify

the timing according to the engine rpm.

At 8777rpm, the timing is reset back to 6 ̊.

At 8905 rpm, the fuel injection is shutdown by cutting the signal from pin #8 (Electronic

ignition module)

to pin #1 (LE-Jetronic) and will resume when the rpm come back down to

this value (This is to avoid over running the engine).

When engine runs over 710rpm, the Electronic ignition module shuts off the ground to the

coil of the starter relay (pin #11). (This is a higher rpm than what the

starter is capable. and at this point the Electronic ignition module assumes that the

engine is running).

If the engine stalls (no more signal from the Hall sensor), the

Electronic ignition module

will shut off the ground to the FI relay and to the coils. (This is to

protect the output transistors and coils).

|

Because the Electronic ignition module send data

to the LE-Jetronic (EFI), it may be necessary to test both units.

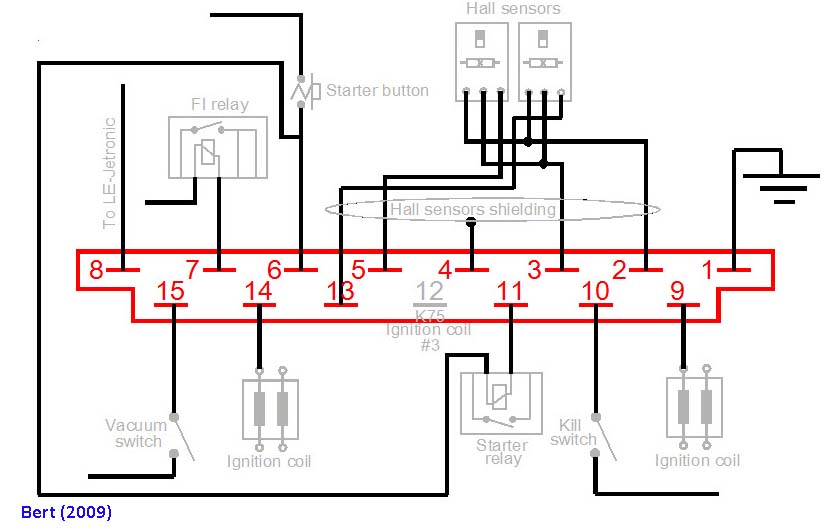

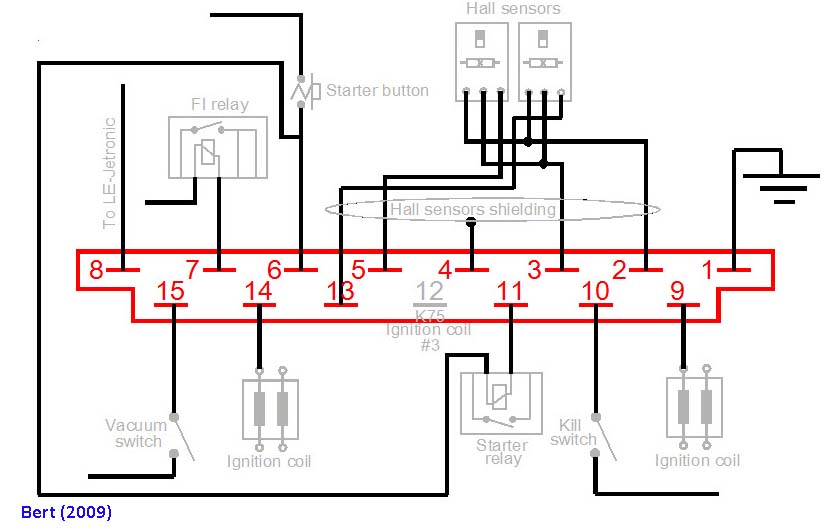

Electronic ignition module female connector:

|

The

following table show the results expected at the

female

connector

and NOT

at the computer pins.

NEVER use your meter on the computer pins! |

|

Electronic ignition module test:

|

|

Pin # |

Function |

Testing mode |

type |

Expected value |

|

1 |

Direct ground |

continuity with ground at the battery |

Ω |

.5 max. |

|

2 |

power to Hall sensors |

control with ignition ON |

Volts |

12v |

|

3 |

Ground to Hall sensors |

continuity with ground at the battery |

Ω |

0 |

|

4 |

Shielding of Hall sensors wires |

continuity with ground at the battery |

Ω |

0 |

|

5-13 |

signal from Hall sensors |

Cannot check with voltmeter/Ohmmeter (see

below for testing) |

|

|

6 |

Signal from starter switch |

When starter is running |

Volts |

12 |

|

7 |

Ground to FI relay |

Engine not running ignition ON |

Volts |

12 |

|

7 |

Ground to FI relay |

When starter is running |

Volts |

0 to 1 |

|

8 |

Signal Engine RPM |

When starter is running |

Volts ~ |

10 to 20 mV |

|

8 |

Signal Engine RPM |

When engine is running |

Volts ~ |

3 to 4 v |

|

9-10-14 |

Ground to primary of ignition coils |

When starter is running |

Volts ~ |

1.5 to 4v |

|

10 |

+12v of Electronic ignition module |

Ignition ON |

Volts |

12v |

|

11 |

Control ground to starter relay |

When starter is running |

Volts |

0 to 1 |

|

11 |

Control ground to starter relay |

Engine running, starter switch depressed, engine rpm < 710 |

Volts |

12 |

|

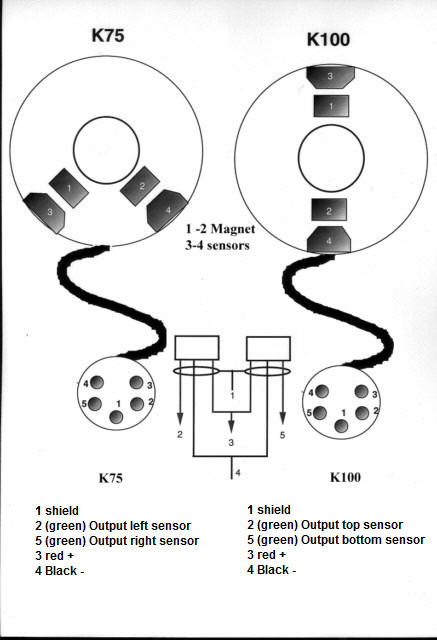

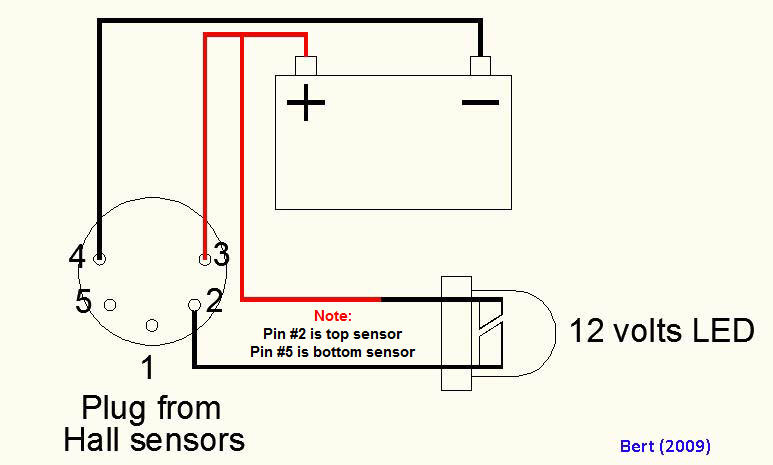

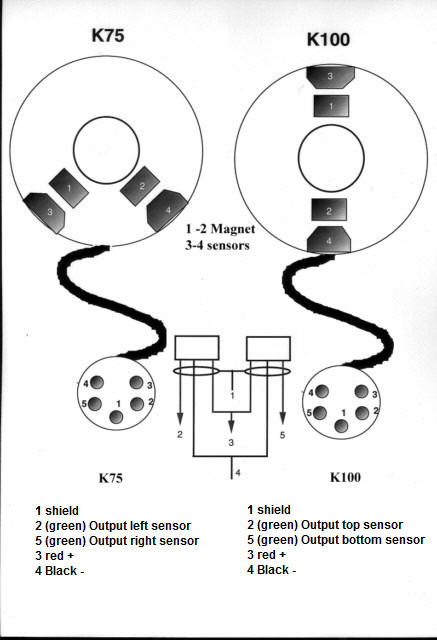

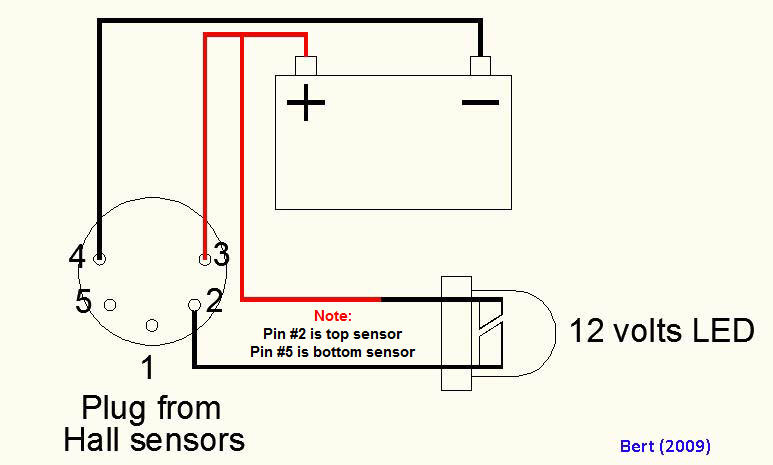

Hall sensors:

Here is how to test them. Pin #2 and #5 on the

Hall sensors plug are the output:

|

WARNING: Never substitute the LED for a bulb.

The excess current drained by a bulb would burn the sensor

As noted on the specs sheet, the maximum load is 40 mA

The 12v LED could be

substituted by a regular 3v but a 470Ω resistor would

have to be installed in series with the the LED |

Any good sensor should light the LED until something metallic, like

a feeler gauge, is introduced in to the sensors gap, the LED will

then go out.

Any sensor

that doesn't light the LED or doesn't go out when the sensor gap is

obstructed is defective.

|

The Hall

sensors are known to fail when hot. They are rated to

operate at a temperature between -40 to +160 degrees

Celsius.

If the bike has a problem only when hot, warm up the sensors

with a hair dryer and test them at different temperatures. |

R bikes and K bikes

share the same sensors. (HONEYWELL

S&C - 2AV54)

The sensors can be purchased

for only $15.00

Just type 2AV54 in Google and you will find a lot of suppliers.

Ignition coils:

First, let’s get a little bit of boring theory about coils….

An ignition coil is essentially

an autotransformer with a high ratio of secondary to primary

windings. The primary and secondary windings are not actually

separated - they share a few of the windings.

The ratio of secondary to

primary turns in an ignition coil is somewhere around 100:1. The

ignition coil is operated directly off a 12 volt source. However,

the ignition coil does not work like an ordinary transformer. An

ordinary transformer will produce output current at the same time

that input current is applied. An ignition coil actually does most

of its work acting as an inductor. When the ignition coil is

connected to the battery, the inductor is 'charged' with current. It

takes a few milliseconds for the current to build up the magnetic

field - this on account of reverse voltage caused by the increase in

magnetic field. During this short charging period, maybe a thousand

volts are produced at the high voltage terminal, not enough to

actually cause a spark. The actual spark is generated when the

breaker contacts open.

Much smaller coils are used and

in the case of the K100. One coil is servicing two spark plugs

(These coils put off about 20kv). It is called a wasted spark

system. In this arrangement the coil generates two sparks per cycle

to both cylinders. The fuel in the cylinder that is nearing the end

of its compression stroke is ignited, whereas the spark in its

companion that is nearing the end of its exhaust stroke has no

effect. The wasted spark system is more reliable than a single coil

system with a distributor. Coils contained in a single moulded block

with multiple high-tension terminals are commonly called a

coil-pack.

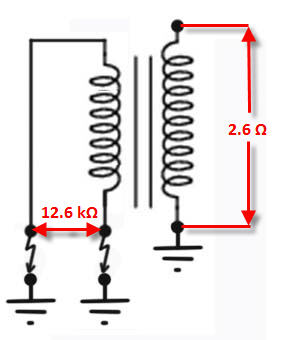

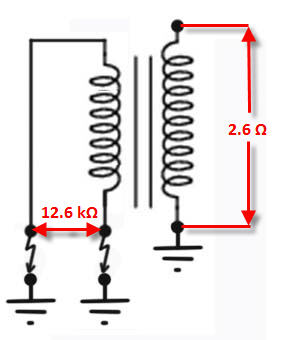

I tested 2 spare K100 coils and the resistance

measured between the 2 high voltage terminals is about 12.6KΩ. The

resistance measured at the primary coil is about 2.6 Ω. This gives

you an idea of what to expect.

What could go wrong with a coil?

You may find a cut in the winding, burnt insulation, crack in the

casing or corroded connections. Your best friend is the Ohmmeter and

a visual inspection at night to locate a crack. A spark will travel

along the crack and will be visible in the dark.

Spark plugs

and ignition wires:

I have read on other forums people

finding after market ignition wires and caps.

This could be a big money saver, but

it can also be a source of concern if you don’t pay attention to the

following points:

The K100 is originally fitted with

Bosch X5DC (or can be fitted with the NGK D7EA). Both are non

resistor spark plugs and here is the reason:

The original BMW spark plug cap

already integrates a resistance of 5KΩ. Similarly, the connector at

the other end of the original ignition cable also includes a

resistance of 1KΩ (The total resistance is 6KΩ).

If you replace the wires with after

market non resistor wires and caps

and keep the original spark plugs, you will run into troubles and

take a chance to damage the output transistors of the ignition

module (resistance of the wire/spark plug will be close to 0).

I believe it is possible to fit a K100 with

after market non resistive wires, but the spark plugs have to be

replaced with a resistive type (Bosch XR5DC or NGK DR7EA). These

spark plugs have a built in 5kΩ resistor.

The X(R)5DC has a thermal index of 5

the D(R)7EA has a thermal index of 7.Even if the thermal

index is different, both are suited to be installed on a K100

engine....

Why is the Bosch having a thermal

index of 5 and NGK has a 7?

Each manufacturer uses its own designation for the heat range:

On the Bosch plugs the higher the

number (from 4 to 8 ) the hotter is the plug. NGK works on the

opposite and goes from 8 to 4 (a lower number indicates a hotter

plug)

The term spark plug heat range refers

to the speed with which the plug can transfer heat from the

combustion chamber to the engine head. It has been found the optimum

combustion chamber temperature for gasoline engines is between 500°C

to 850°C. When it is within that range it is cool enough to avoid

pre-ignition and plug tip overheating (which can cause engine

damage), while still hot enough to burn off combustion deposits

which cause fouling.

The spark plug can help maintain the

optimum combustion chamber temperature. The primary method used to

do this is by altering the internal length of the core nose, in

addition, the alloy compositions in the electrodes can be changed.

This means you may not be able to visually tell a difference between

heat ranges. When a spark plug is referred to as a “cold plug”, it

is one that transfers heat rapidly from the firing tip into the

engine head, which keeps the firing tip cooler. A “hot plug” has a

much slower rate of heat transfer, which keeps the firing tip

hotter.

For information

here is a list of spark plugs fitted for the K100:

- Bosch X5DC

- Beru 12-5 DU

- Champion A85YC

- NGK D7EA

- Denso X22ES-U or the Iridium IX22

|

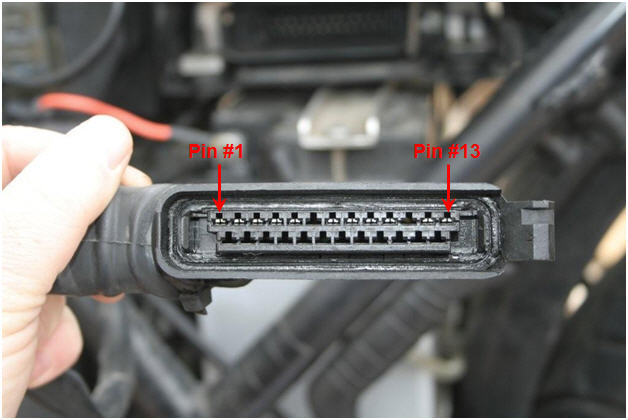

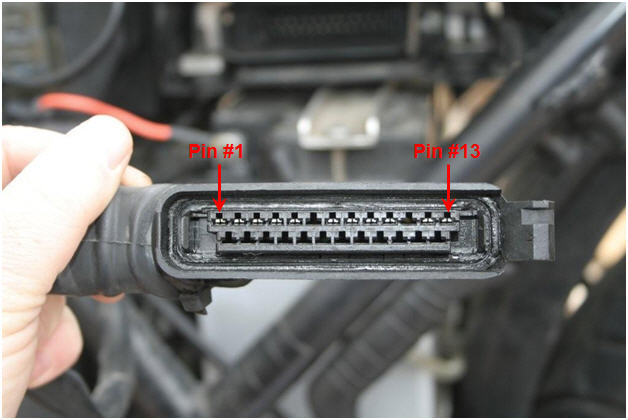

LE-Jetronic female connector:

|

The

following table show the results expected at the

female

connector

and NOT

at the computer pins.

NEVER use your meter on the computer pins! |

LE-Jetronic (EFI) test: |

|

Pin # |

Function |

Testing mode |

type |

expected value |

|

1 |

info on engine rpm |

When starter is running |

Volts ~ |

10 to 20mv |

|

2 |

Idle switch (idle) |

Ignition ON, FI relay ON, throttle OFF |

Volts -- |

12v |

|

3 |

Idle switch (full throttle) |

Ignition ON, FI relay ON, throttle full |

Volts -- |

12v |

|

4 |

starter running |

Starter switch depressed |

Volts -- |

12v |

|

5 |

Ground air flow meter |

|

Ω |

0Ω |

|

7 |

Info on air flow meter |

between pin#7 and pin #5 |

Ω |

See below for data collected on 5 units |

|

7 |

Info on air flow meter |

between pin#7 and pin #8 |

Ω |

|

8 |

Info on air temperature |

between pin#8 and pin#9 |

Ω |

|

9 |

Power (+) to computer, air flow meter and injectors |

When starter is running |

Volts -- |

12 |

|

10 |

Water temperature |

Between pin #10 and ground |

Ω |

2.5KΩ @20 ̊C

300Ω @ 80 ̊C |

|

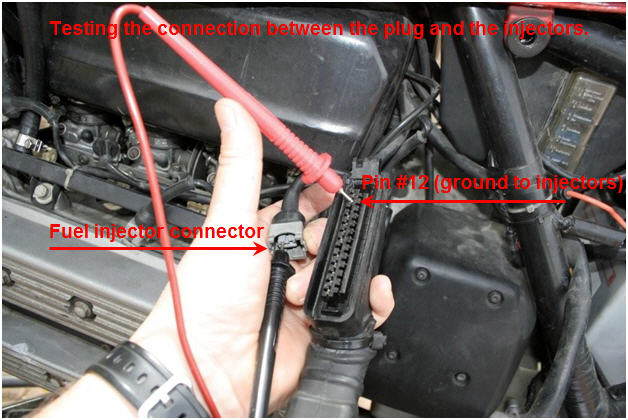

12 |

Ground to injectors |

Between pin #12 and pin #9 |

Ω |

1 injector 16Ω |

|

|

|

|

Ω |

2 injectors 8Ω |

|

|

|

|

Ω |

3 injectors 5.33Ω |

|

|

|

|

Ω |

4 injectors 4Ω |

|

13 |

Ground |

Between ground of battery and pin 13 |

Ω |

0Ω |

|

Important note

about the signal at pin #1:

As seen before, the ignition computer may

give you the ignition at the sparkplugs, but it may fail

to send a proper signal to pin #1 of the FI computer.

|

This is the EFI

connector

where the test has to be done |

|

|

Air flow meter:

|

Test can be done directly at the airflow

meter. (Pin # 5-7-8-9)

If you are checking the airflow

meter at the injection computer plug, it must be done

with the fuel tank electrics unplugged. Otherwise pin 9

is earthed via the fuel pump and all the readings between

pins 5-7-8-9 are wrong. The airflow meter can be tested by

applying 12v between pins 5 and 8 and measuring the voltage

across pin 5 and 7 while moving the vane. The reading moves

smoothly between about 2v and 12v.

The following resistance value reflects test

from 3 people on 5 different units. |

|

Pin 7-5 |

Pin 7-8 |

Pin 8-5 |

Pin 8-9 |

Status |

|

Vane closed(value changes with vane position) |

Vane closed(value changes with vane position) |

Constant (not affected by vane position) |

air temperature |

|

|

152 |

403 |

361 |

207 |

Have problem starting the bike with this unit |

|

82 |

334 |

363 |

207 |

OK |

|

93 |

358 |

360 |

202 |

OK |

|

76.6 |

334 |

360 |

205 |

OK |

|

66 |

161 |

33 |

132 |

Bike doesn't start |

|

|

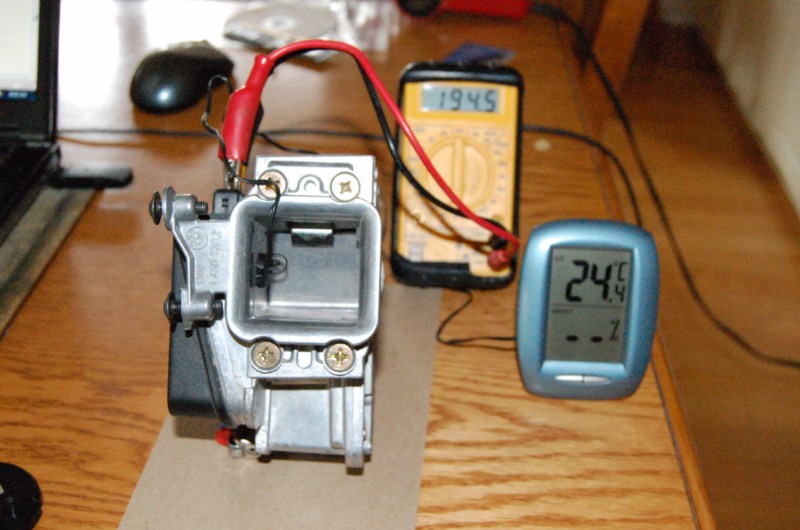

Air temperature sensor test

(in the

mouth of the Airflow meter)

Values obtained between pin #8 and #9 of the airflow meter.

Under 30 degrees Celsius, the value of the resistance is

decreasing by only 1 to 2Ω per

degree.

A corroded connection will greatly affect these values.

|

|

Here is a picture of the

testing.

The thermometer sensor is placed in the mouth of the

airflow meter.

|

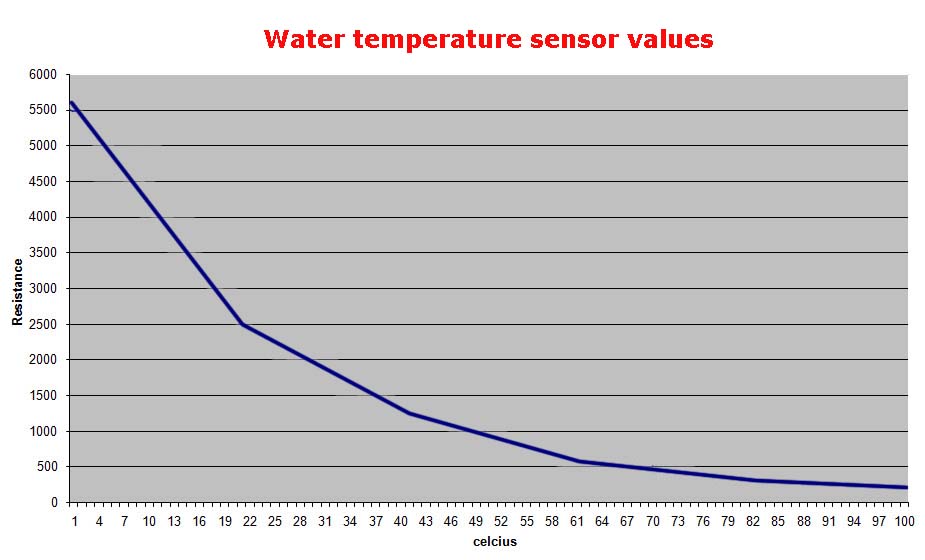

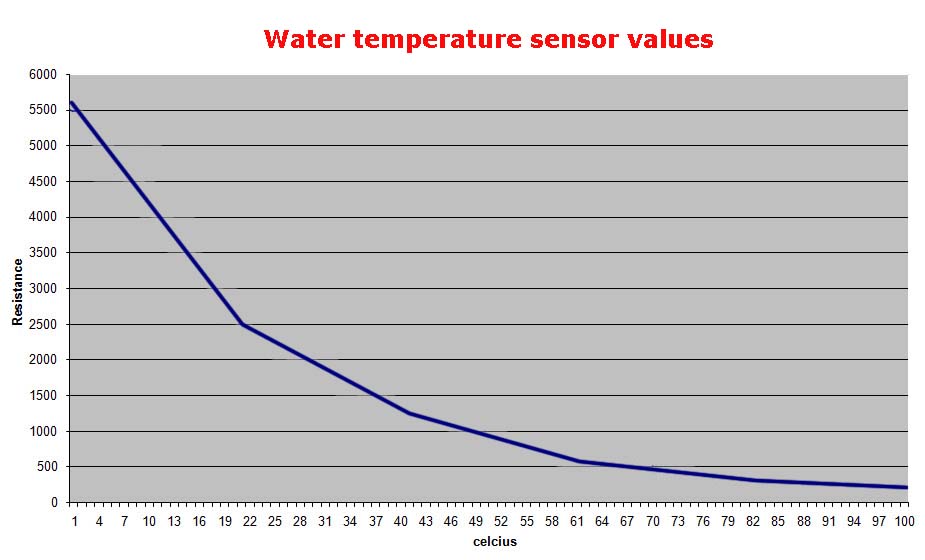

Water temperature sensor:

|

I have read that when the bike is

overheated, it will not start until it cools down. If a

problem occurs with the water temperature sensor (bad unit

or corroded connections), you may encounter difficulties to

start the bike or worst, it will not start at all. I have

not found any documentation about this, but just reports

from other bikers.

One of the lead of the water temperature

sensor is feeding the EFI, and I believe that it is possible

that The FI would be shut down until the engine temperature

goes down.

In order to shut down the FI, the computer will stop

energizing the FI relay. |

Take a pot of boiling water, immerse a thermometer.

Plug your ohmmeter to the sensor and have the tip of the sensor immersed in the

water.

Let the water cool down and get the value for every drop of 10o

Celsius

Here is the schematic of the temperature switching unit:

|

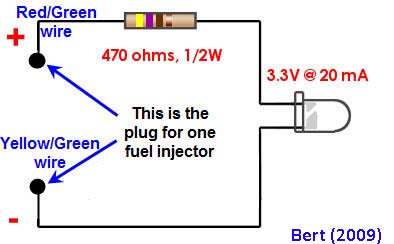

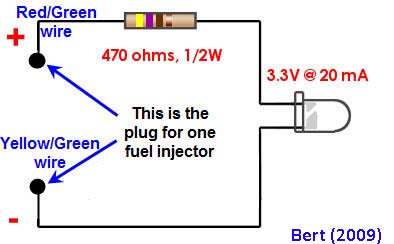

Testing the electrical power at the fuel injectors:

Because of the injection time varying from 1.5ms to 9ms.,

it is

best is to use an LED to test the EFI computer output.

A cheap regular LED should work for this purpose but they are rated for

3.3v/20mA.

A resistance would have to be installed in series with the LED in order to drop

the voltage to 3.3 volts.

At some hobby stores (Radio Shack, The Source..) you are able to buy 12V LED and

the resistor won't be needed.

The following schematic shows the testing at the fuel injectors. (Red/Green and Yellow/Green are the 2 wires feeding the injectors)

|

|

Testing if the Fuel injector relay provides a positive voltage to the injector:

The positive should be permanent

as long as the ignition is ON, the kill switch is on the "running" position

and the starter button is pressed.

The positive connection to the injectors is also feeding the airflow meter, the

idle switch and the fuel pump. If you get a low voltage, disconnect these 3

devices and the FI computer. If one is bad it can drain the voltage.

If you get the 12 volts, plug everything back checking the voltage at the

injectors after each device is plugged back.

|

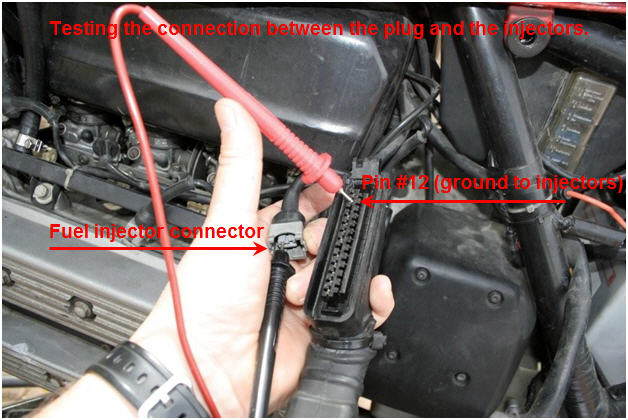

Testing if the EFI computer is sending the "pulsing"

negative to the fuel injectors:

(The test of the EFI relay has to be conducted first)

When you are pushing the starter button, you should get one

pulse for each rotation of the engine. (The 4 injectors are

working together).

|

|

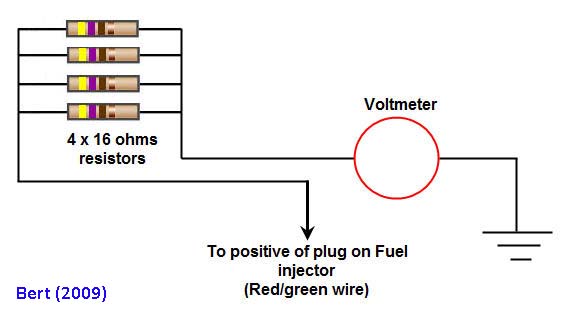

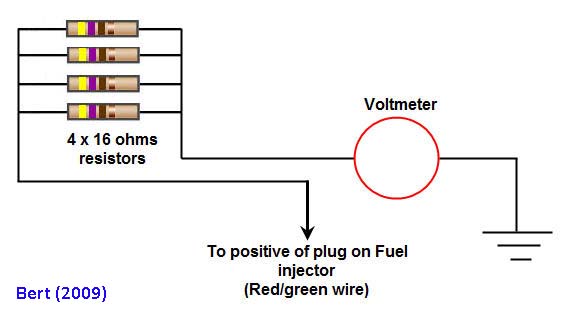

We know that each fuel injector coil has a 16

ohms resistance. If we want to test the the circuit in "real"

condition, it is easy to disconnect the 4 fuel injectors an

insert 4 16 ohms resistances on the circuit.

Here is the way that I would test it:

|

Testing the fuel pressure:

|

To test the system fuel pressure, install a manometer in

parallel with the fuel pressure hose. If the fuel pump and the external pressure

regulator are working correctly, you should read close to 36psi

on the gauge |

To test the fuel pressure

output of the pump, install the manometer right at the pressure

port of the tank.

You should read about 65 psi.

The internal relief valve of the pump should keep the pressure

to this value.

A lower value reflects a bad fuel pump or a bad fuel filter.

A higher value reflects a problem with the built in relief valve. |

|

|

|

More reading on the LE-Jetronic system:

Notes on LE-Jetronic

LE-Jetronic seminar by Peter Florance

If you are looking for technical information on the K100,

the K100 forum is the place to go.

Bertrand Vogel (Crazy Frog)

|